Seeq: Industrial data analysis for your production operation

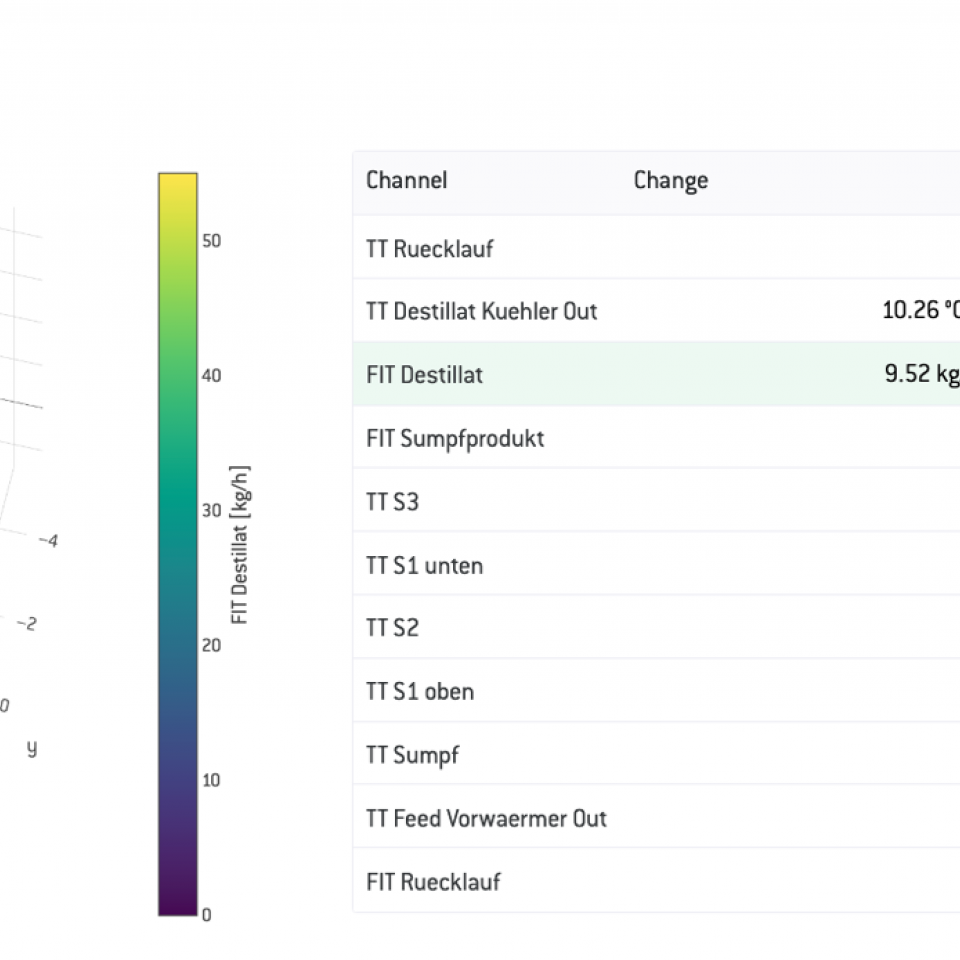

Seeq is a software platform for the analysis and visualization of industrial time series data that has been specially developed for production companies in industries such as chemicals, pharmaceuticals, energy and food.

It combines powerful tools for data cleansing, modeling and machine learning with a user-friendly interface that can be used without programming knowledge. With features such as real-time dashboards, automated reports and seamless integration with existing data systems such as Historian databases (e.g. AVEVA PI) or cloud solutions, Seeq helps companies to enable more efficient processes and informed decisions.