CTE project process: a proven process that allows active exchange within the project team

Quality is no coincidence - from start to success and beyond. From the initial idea to successful commissioning, we accompany you through the entire lifecycle of your project - and remain at your side afterwards.

Our standardized project process and ISO 9001-certified quality system ensure transparency, the highest quality standards and a partnership you can count on. This is how added value is created!

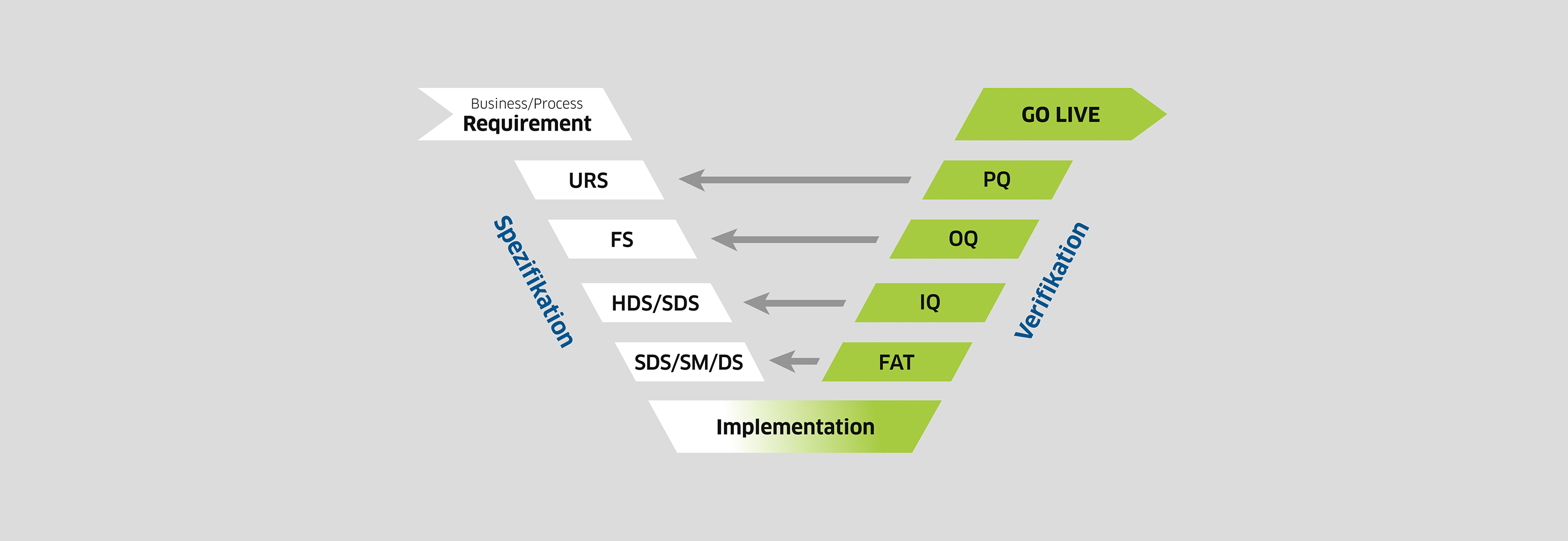

Our way of working is based on the proven V-model, which we adapt flexibly to modern methods such as Agile, SCRUM or CRISP. We follow the principles of what - how - do - test and combine proven structures with innovative approaches to implement your project efficiently and future-proof.