OT Data Layer - How the Right Integration Creates Added Value

The term 'OT DATA' now encompasses more than just long-term archiving systems. As the foundation for data exchange and analysis, the OT Data Layer in integrated environments is now the central hub of horizontal and vertical data communication. But what added value, opportunities and risks does the introduction of an OT DATA layer in global environments entail?

OT DATA was originally concerned with meeting the legal retention periods for all production data. This was initially done on the individual standalone devices. With networking in the automation environment, the path led to Historian systems, which 'collected' all data centrally in order to store it in the long-term archive.

From Data Repository to Data Hub

Now that many companies have implemented a long-term archiving system (DATA Historian) and almost all data is collected, the path is moving away from the 'data repository' to the 'data hub'. The aim is to use 'the gold of information', i.e. the added value based on the data, to gain insights from it.

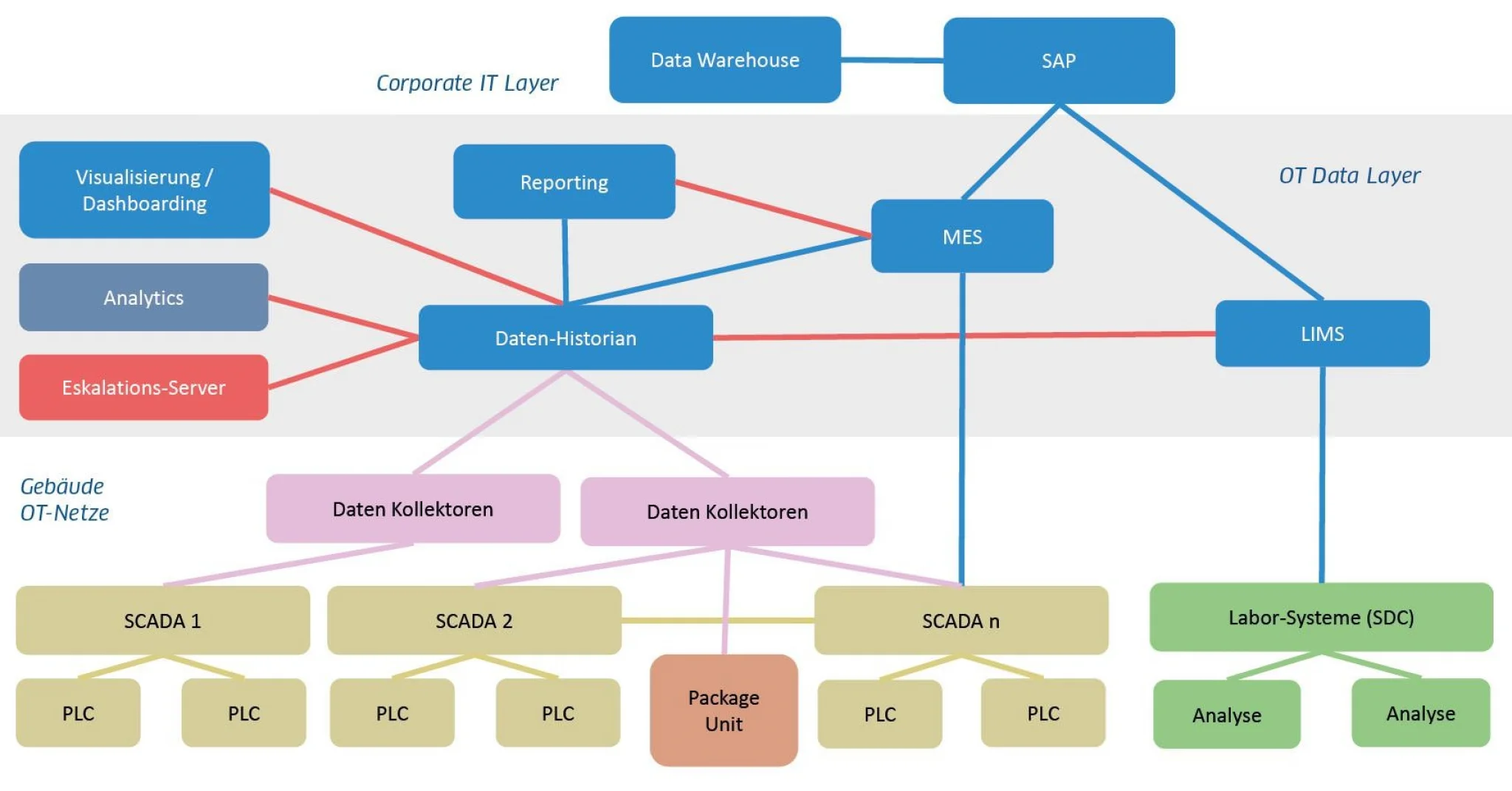

In modern OT environments, the long-term archiving system has become a so-called OT data layer, which usually contains many other subsystems. In addition to the DATA Historian, an MES (Manufacturing Execution System) and/or a LIMS (Laboratory Information and Management System) are an integral part of many environments. The OT data layer also serves as an interface to higher-level Enterprise Resource Planning (ERP) systems such as SAP.

Depending on the environment, the OT data layer can be located directly in a production building at one site, globally distributed across several sites or now also in private or public cloud environments.

Common components in the OT data layer also include reporting, visualisation and dashboarding systems. This allows data and information from different systems to be consolidated, visualised on info displays or dashboards or presented in reports.

Another point that is becoming increasingly important is that (non-critical) maintenance data, for example, is exchanged directly via the OT data layer with various stakeholders / suppliers across company boundaries. However, cloud-based data storage allows relevant data to be made available to third parties in a secure and controlled manner.

Vertical Integration

For many customers, we are directly involved when existing or new production lines are 'vertically' integrated into the existing infrastructure. This refers to the vertical data flow across the various network layers. A typical scenario looks like this:

SAP sends order data to the MES

MES sends the order data directly or via PI system or directly via OPC to the control system

The control system on the production line confirms receipt of the data

Once the production order has been completed, the control system reports the end and all relevant alarms and deviations back to the MES

In the MES, batch release takes place via "Review by Exception"

This enables consistent data exchange between the individual systems that cannot be manipulated from a data integration perspective. All relevant data can also be visualised simultaneously in dashboards and later displayed in reports.

Architecture and Security

In recent years, we as CTE have integrated an OT DATA layer into existing customer environments in many projects or helped to develop and introduce it in new architectures.

What's most important is to define the requirements in detail before starting and to create a clear concept for implementation. The specifications of the respective corporate IT department must also be complied with and their security concepts taken into account during planning.

IT/OT security is a risk factor that needs to be taken into account, especially for OT data cloud solutions. To this end, a data flow concept defines exactly how the data flow from the data source via the various network layers to the higher-level systems should take place.

An important part of this is that data is preferably 'pushed' from lower-level systems to higher-level systems and that connections are not established from higher-level systems to lower-level systems. This means that the firewalls don't have to be opened for incoming network traffic and therefore, offer the highest possible level of security.

Advantages and Added Value

Not all customers or users have the same expectations in terms of data in the OT data layer. Depending on the user group and type of use, different requirements apply to the presentation and timeliness of the data.

A process employee in production usually needs real-time data in the form of a visualisation display (e.g. OSIsoft PI Vision) for the exact system they are currently working on. Employees from the research department, on the other hand, are interested in the data of the corresponding manufacturing processes in order to be able to optimise the production processes based on the knowledge gained. Plant managers, on the other hand, usually want to see the most important key performance indicators (KPIs) for their entire plant on one or more dashboards.

In large corporations, increasingly global OT data layers consolidate important production data from all locations worldwide in order to compare them and gain insights across plants.

This makes it possible for the relevant user group to compare production processes and the efficiency of locations worldwide. Advanced analytics systems such as Statsoft, Seeq or Trendminer are employed, which use artificial intelligence to automatically recognise patterns and gain insights from the recorded data. These in turn are used to optimise costs and reduce errors so that, for example, production processes can be continuously optimised.

"The Real Gold" as a Goal

The OT data layer will become even more important in the future to ensure a secure and modern data infrastructure as digitalisation progresses.

There is never one right solution. What is crucial is to have the data infrastructure designed in such a way that it serves the respective requirements and ensures secure data storage and data communication at all times.

Moreover, not all eventualities have to be considered right from the start. The OT data layer grows with the requirements and can be supplemented and expanded at any time.

The greatest added value is created when data that is 'only' collected becomes information that enables the company to gain insights from such data (i.e., the real gold).