A comparison of process control systems for the automation of production plants

Which automation system is the right one? ControlTech Engineering AG (CTE) from Liestal compares and supports systematic decision-making. Whether in industrial production, in energy and water supply or in the pharmaceutical industry - automation systems must be precisely tailored to the respective application.

How do we at CTE go about finding out which process control system is the right one? We compare according to predefined criteria. This always involves structure and design, sufficient flexibility for every requirement, good interfaces or support for industry standards such as ISA88/MTP, ProfiNet, OPC-UA, MQTT, etc.

We pay attention to the manufacturer's support as well as to license models and scalability during installation. We keep an eye on the capex costs of the basic installation as well as the anticipated scaling and corresponding opex costs. In this way, we avoid unpleasant surprises and unforeseen high follow-up costs.

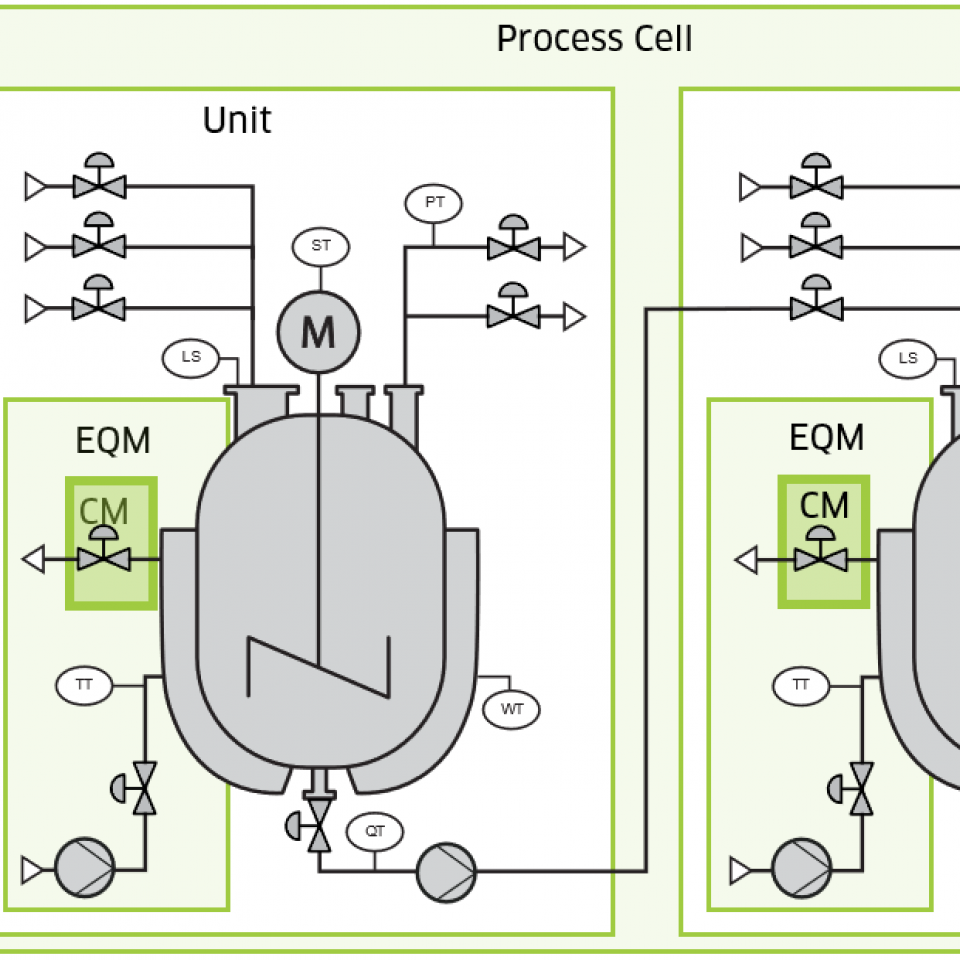

Equally important is the clear presentation of the system components (libraries, software and hardware requirements). We also pay particular attention to customer requirements with regard to modularization. A central goal is to design software in such a granular way that several programmers can engineer in parallel and independently of each other and copy effects can be efficiently exploited by means of instantiation - both initially and in the case of large-scale software adaptations. This is not handled in the same way in all systems.

No major costs for small installations

Once we have evaluated the above criteria together with our customers, we look for possible solutions. In doing so, we focus on common process control systems that we use with the necessary expertise. We would like to take a closer look at the following three systems in this technical article: Emerson's DeltaV, PCS 7 from Siemens and zenon from Copa-Data.

DeltaV

DeltaV is a fully-fledged DCS (Distributed Control System) with a focus on consistency, online changeability and batch/S88 support. Very well suited for large scaling and deterministic online changes.

PCS 7

PCS 7 is a well-established DCS from the Siemens world, with a modular structure, flexible configuration and high PLC speeds at the control level, with central engineering (Simatic Manager) and fully tested components.

zenon

Zenon comes from the very sophisticated SCADA world, but already with virtual soft-PLC. Deliberately flexible, collaborative and hardware-independent, it is less of a classic, more open DCS. Ideal in heterogeneous field levels and for modular automation.