A large pharmaceutical company from the Basel area wants to break new ground in the field of MTP and has teamed up with zenon manufacturer COPA-DATA and Gold Integrator ControlTech Engineering from Liestal. Based on the new MTP standard, a pilot project was defined to test the modular and flexible design of automation solutions in the process industry, regardless of specific requirements.

MTP stands for Module Type Package and is used in the context of automation in the process industry to facilitate the integration and exchange of automation solutions. As the MTP standard is relatively new, the aim is to gain new insights through pilot projects. For this reason, a large pharmaceutical company, the zenon experts from COPA-DATA and the automation specialists from CTE have gathered joint experience that brings added value to everyone. In addition, it was also evaluated how frequently established PCS7 control systems can be used in the MTP context.

With MTP, automation modules can be integrated into a production environment according to the plug & produce principle. This means that modules can be added, removed or replaced quickly and easily - even if they come from different manufacturers. This in turn makes it easier to adapt production systems to changing requirements. MTP is possible for new systems as well as existing systems - regardless of the manufacturer. For new systems, programming and the visual interface (HMI) can also be worked on in parallel to save time during development. Without MTP, collaboration is more difficult as customers have to commit to individual software solutions. With the pilot project at the pharmaceutical company, COPA-DATA and CTE were able to generate new knowledge and test it directly. This puts CTE in a position to offer practicable solutions to future customers or to support them with developments.

We get you MTP-Ready!

MTP supports the concept of modular automation, in which production systems consist of standardized, modular units. These modules can be developed and tested independently before being integrated into the overall system. This modular automation is particularly interesting for large companies because it allows them to respond more flexibly to the market. Thanks to the independent development, the individual modules can be developed and tested in parallel. This makes automation significantly faster.

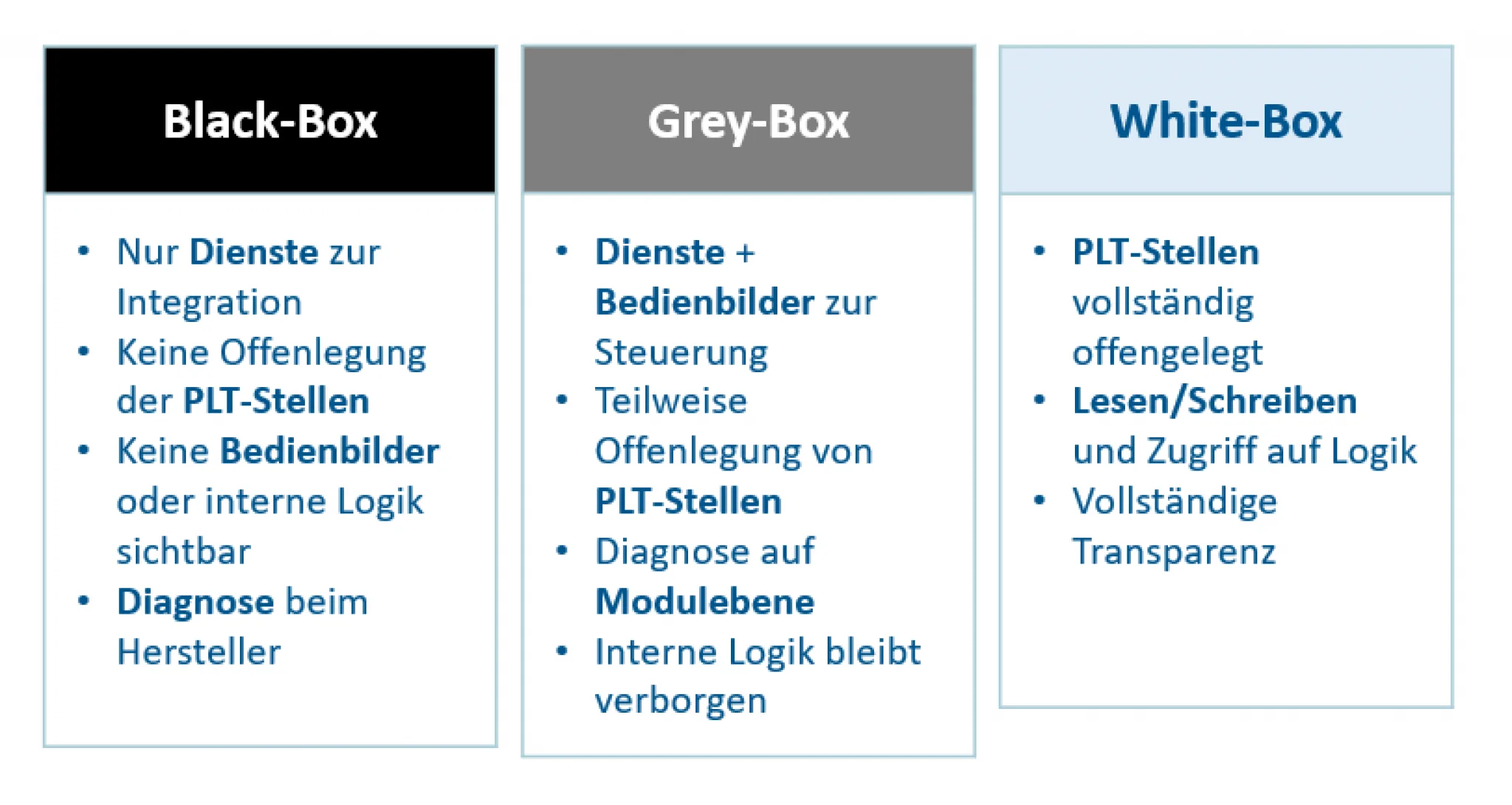

What many people don't know: MTP does not specify the level of transparency of the equipment. It is still up to the provider or the agreement between customer and supplier to decide how much information and influence the MTP interface provides. This means that MTP offers suppliers every possible level of integration and a correspondingly wide range of business models.

The pharmaceutical company's pilot project involved integrating an existing system from an existing ultrafiltration plant, which worked with an S7 control system, into the zenon visualization system with the help of MTP. Zenon is a SCADA and HMI software platform that was to replace the previous S7 control system and use the existing programming (S7). Right at the start, the zenon experts from COPA-DATA created a customized setup in the zenon development interface so that CTE could specifically connect the interface to the S7 project. Communication between zenon and the S7 controller works: Data can be read and written. The equipment can now be controlled using the MTP interface in zenon. The software offers a user-friendly environment for customizing visualization and control. Thanks to MTP, the integration of an existing S7 project could be controlled using MTP.

The proof of concept is currently being finalized. In the next step, the project team will present the findings to the clients and demonstrate what is possible. Thanks to the new findings and MTP experience, everyone involved in the project has gained added value. CTE can already score points with MTP expertise, even though the technology is still relatively new. Project manager Denis Krüger comments: "There are no standard solutions (yet) for existing systems, so we had to develop new findings and solutions with experts from both areas."

Denis Krüger cites his prior knowledge of both worlds as a major advantage. CTE is a Gold Integrator of COPA-DATA and a Solution Partner of Siemens. "Our automation specialists have experience thanks to their SCADA expertise. Thanks to good preparation, it was possible to combine the two worlds in a targeted manner," says Denis Krüger, looking back.

The pilot project is not yet complete. After the presentation to the client and the customer's automation experts, the next steps need to be defined. One thing is certain: the future of MTP in automation technology looks very promising. It can be assumed that more and more manufacturers will offer a solution with MTP in the future. To support this decision, it is important that the first pilot projects are successful. MTP's ability to seamlessly integrate different modules and systems is crucial for creating flexible and intelligent production environments.