Finding the right automation system - systematically finding the optimum solution

When starting a new automation project, the question of the right system often arises. New systems are constantly coming onto the market, existing ones are being developed further - and companies are faced with the challenge of finding the best solution for their specific requirements. But which automation system is the right one? And how can you ensure that the decision you make will be sustainable in the long term? CTE provides support with systematic evaluation.

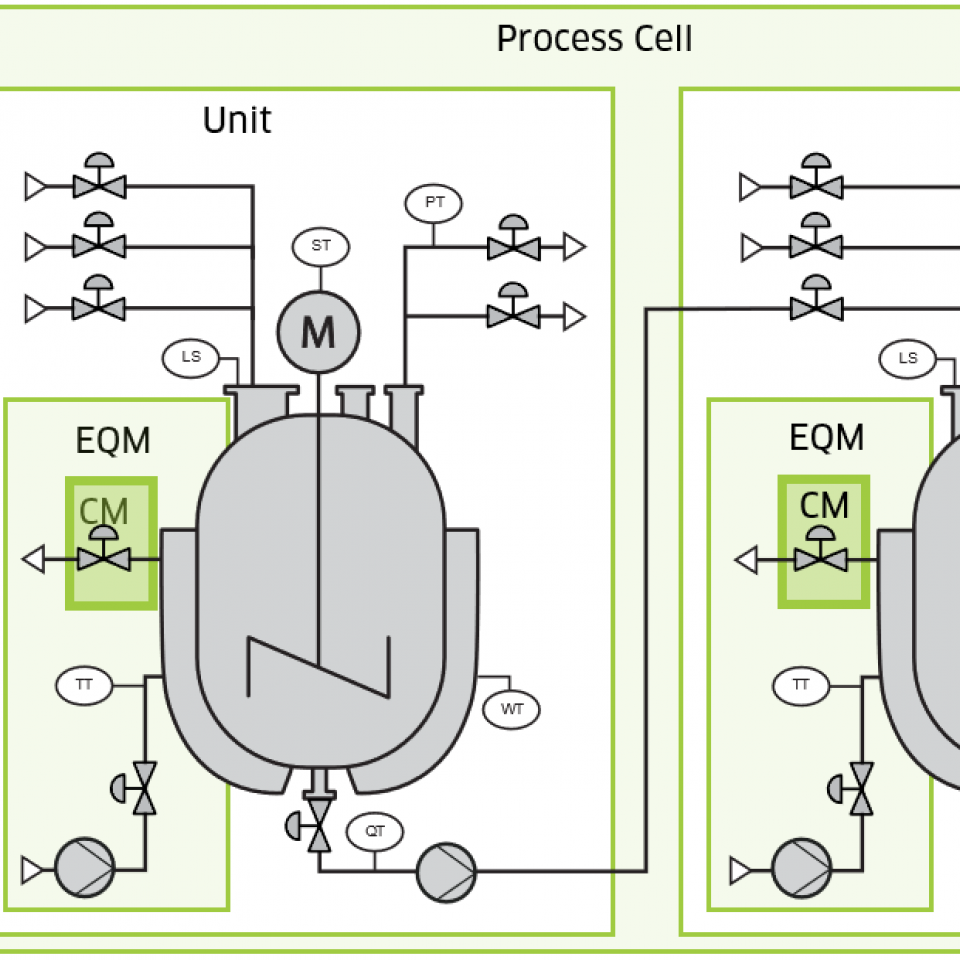

Whether in the laboratory, in classic mechanical engineering or in pharmaceutical production - automation systems must be precisely tailored to the respective application. While comprehensive control systems such as PCS7 or DeltaV are ideal for large-scale industrial plants, simpler controllers often meet the requirements of laboratory environments better. If you make a hasty decision, you run the risk of the chosen system not being flexible enough later on, resulting in unnecessary complexity or increased license costs.

CTE knows these challenges and supports companies independently in systematically finding the best solution. Thanks to our close cooperation with leading system manufacturers, we can offer objective advice and identify the optimum automation solution for each company. Our employees are constantly undergoing further training so that we can implement demanding projects using state-of-the-art technology.

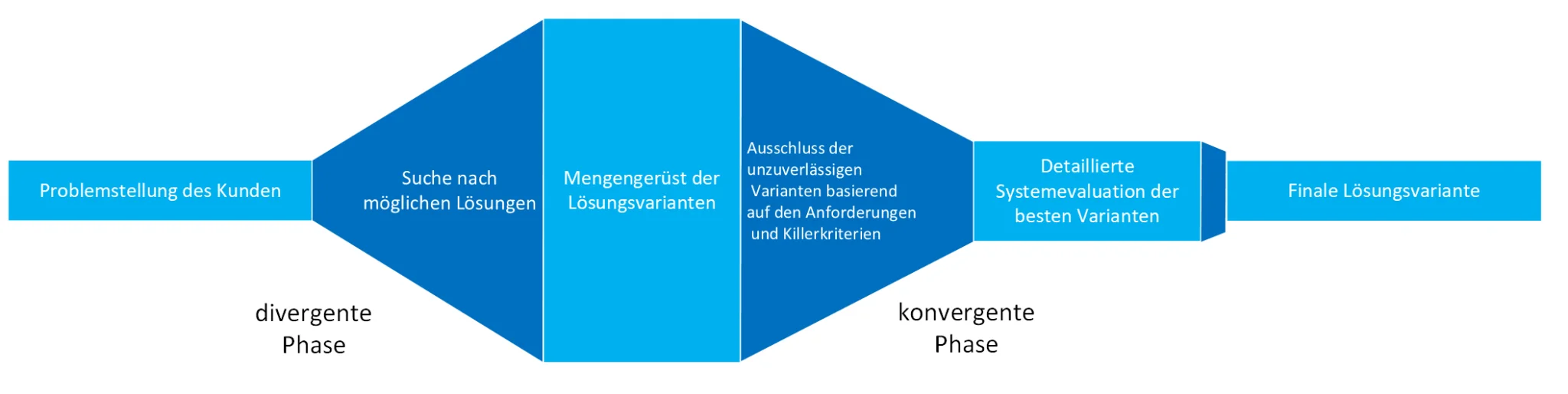

Systematic evaluation instead of gut feeling

But how do we support our customers in their search for the right system? The selection process begins with a clear definition of the functional requirements. Together with the customer, we determine the specific needs of the project - from the required flexibility and scalability to regulatory requirements and integration options.

Based on these requirements, we compare the options with our comprehensive internal market overview. Thanks to our experience and close cooperation with leading system manufacturers, we know which systems are particularly suitable for which requirements. This allows us to narrow down the selection in a targeted manner and means that we do not have to carry out a complete market analysis from scratch for every decision.