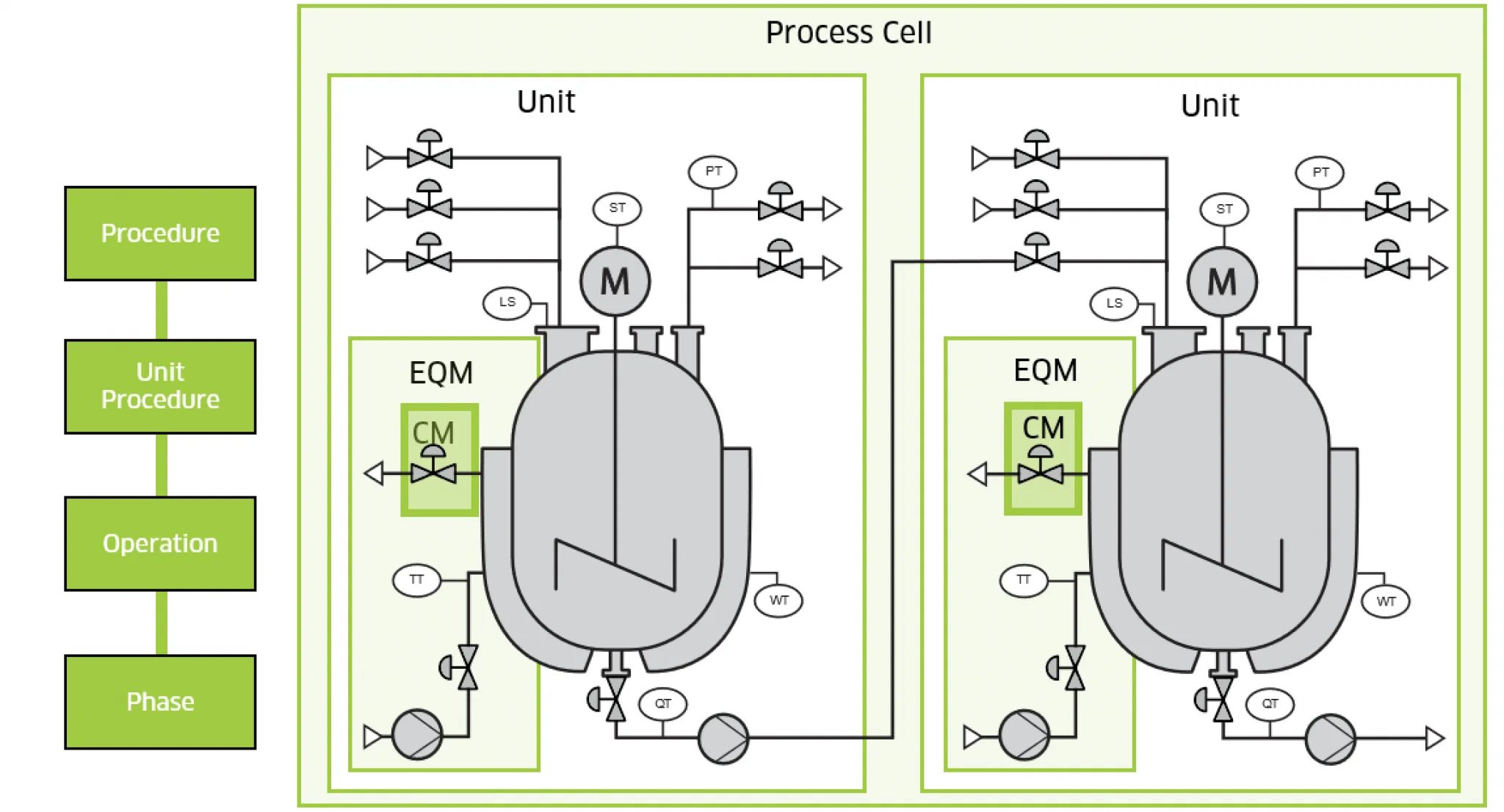

Industrial process automation according to ISA-88 standard

A standardized procedure provides orientation and helps to automate production systems.

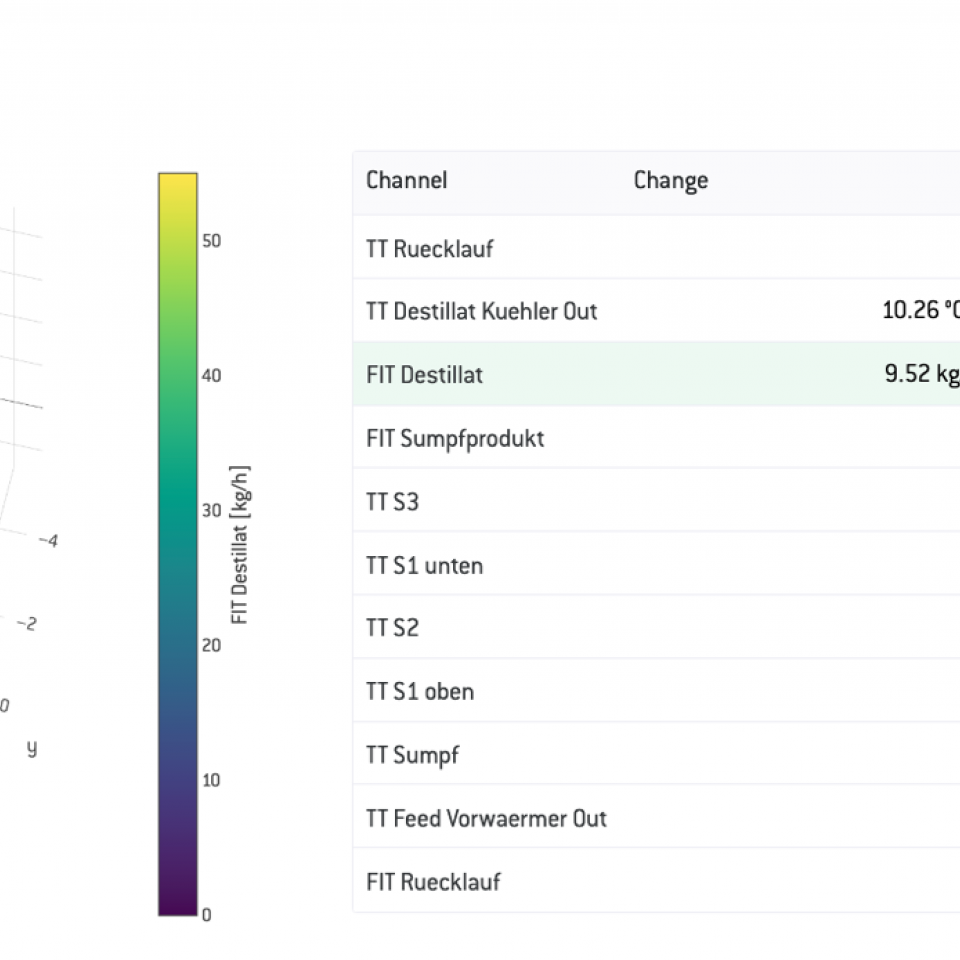

ControlTech Engineering AG from Liestal has customers from various industries. A standardized concept for automated production helps all CTE departments and everyone involved to develop the same understanding.

Brief overview

added value for our customers: