SCADA or Control system?

Any attempt to clearly distinguish between SCADA and control system is bound to fail. All internal discussions and even those in online forums have come to no clear conclusion. This is understandable, as both are located at the process control level of the automation pyramid.

In the past, 1 control system for 1 machine with 1 operating panel was clearly a SCADA system and X control systems with Y operating stations for an entire production plant was a control system, but today, thanks to technical progress, this is no longer clearly recognisable.

Not Identical, But Similar

Of course, not every SCADA system can do everything that a control system can offer. But in many aspects, the two control systems have come closer together: Whereas in the past every function had to be programmed for SCADA, while in the control system the integrated modules only had to be configured, nowadays there are tested libraries for every level, which ensure uniform, validated and time-saving software development.

All the advantageous features such as modularity, standards and consistency that a control system provides for engineering can also be found in the modern SCADA scope.

The boundaries are less clear and overlap, but have by no means disappeared. For example, a SCADA system reaches its limits when there are several thousand IO points. The scope is no longer manageable.

The fact that SCADA software often does not come with its own hardware for the control and field level, thus requiring multiple engineering tools, also highlights the difference compared to the comprehensive package of a control system. On the other hand, SCADA still offers developers the flexibility and openness to adapt every feature to their needs, which is often not the case with a control system due to its proprietary structure.

Which is better?

Over the past 30 years, CTE has designed, planned and implemented a number of SCADA and control systems. Products from Siemens, ABB, Emerson, GE Fanuc, Rockwell and Copa-Data have been used. More important than the question of whether one is better than the other is what the requirements are and how the system can be planned and implemented. Even the best control system can end up in chaos if it's not planned properly. On the other hand, a structured SCADA project can provide a customer and their system with exactly what they need.

CTE pursues this goal in its daily work: to provide customers with the solution they need.

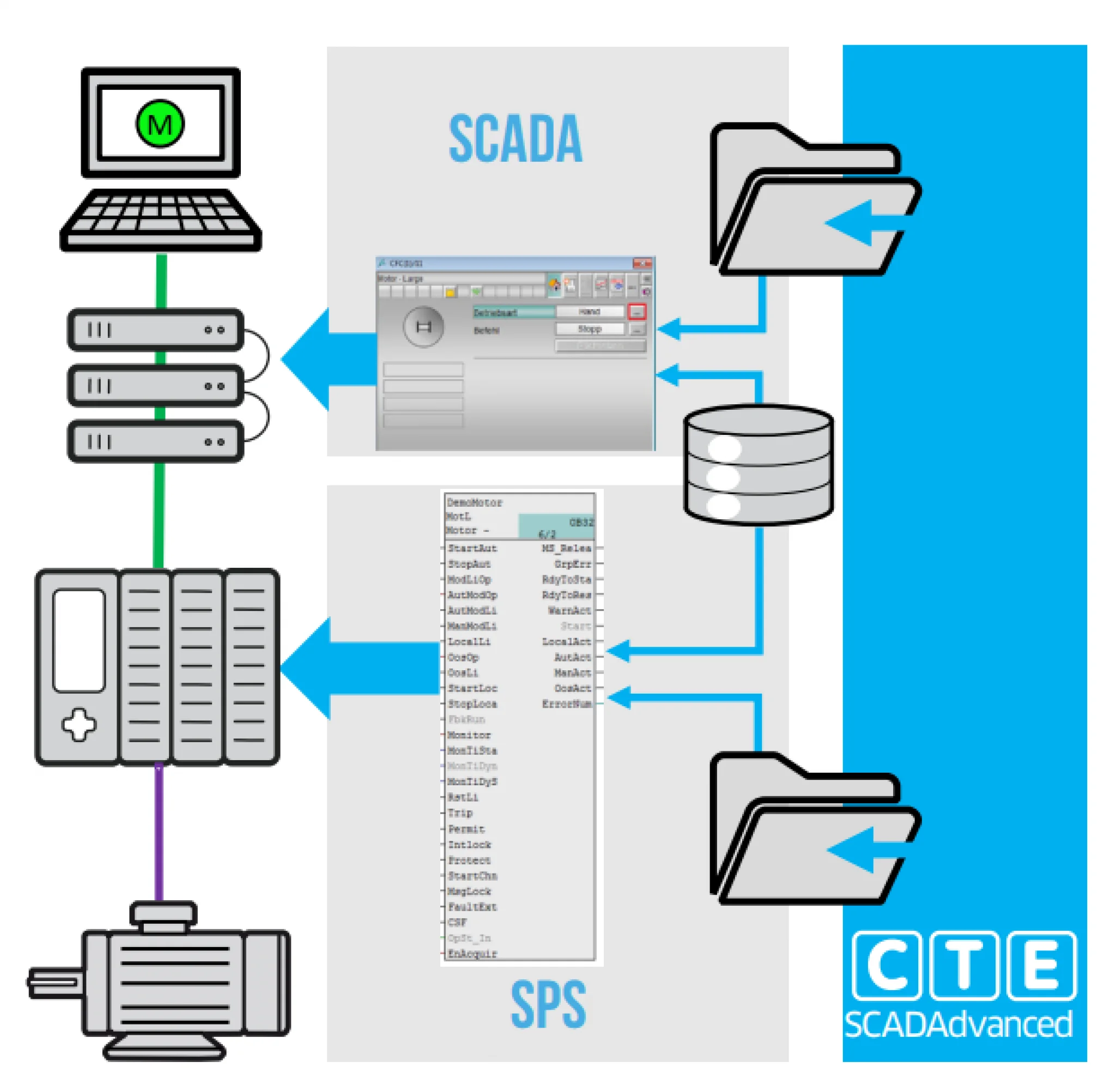

Functionally, a SCADA is in no way inferior to a control system. From alarm reporting systems, data archives and audit trails to user and authorisation management and batch control, its offer is comprehensive. For successful and efficient implementation, however, more attention must be paid to the execution phase than is the case with a control system. Once the structure (preferably in accordance with ISA88), actuators and sensors have been defined for the control system, many software objects can be created in one step using generators thanks to modularity. In SCADA, this requires several steps, as the control part must be configured separately from SCADA.

SCADA Benefits

A SCADA solution is often a good choice for retrofitting existing systems, as it can be easily connected to the existing hardware. This keeps the costs manageable while still increasing the level of automation. Independence from hardware can also be an important factor for international companies. Thanks to the standardised SCADA software interface, the interaction between man and machine remains identical, regardless of the installed control systems.

Thanks to their flexibility, scalability and low cost, SCADA systems often offer everything the customer needs for a little extra effort.

Control System Benefits

In the case of a new installation on a greenfield site, however, the full benefits of the automated engineering functions of a control system can be fully realised. The time advantage gained from using standard libraries and generators offsets the higher investment costs.

In terms of maintenance and updates, there is a lot to be said for the control system. Because with a central database, there is no need to maintain several independent systems. This saves time and money and reduces susceptibility to errors.