Efficient automation for production plants (PLS) – modular and future-proof

ControlTech Engineering AG (CTE) specializes in a standardized approach to automating production systems. This gives you greater efficiency, productivity and safety. We analyze existing structures in order to optimize them together with you.

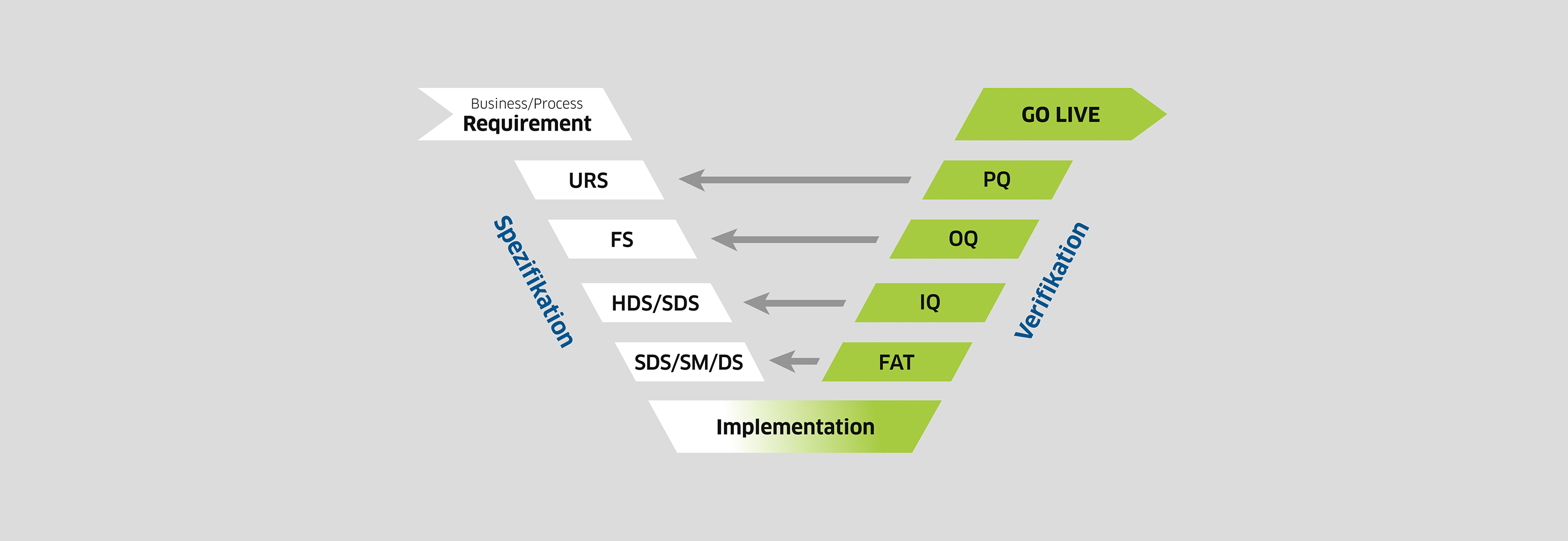

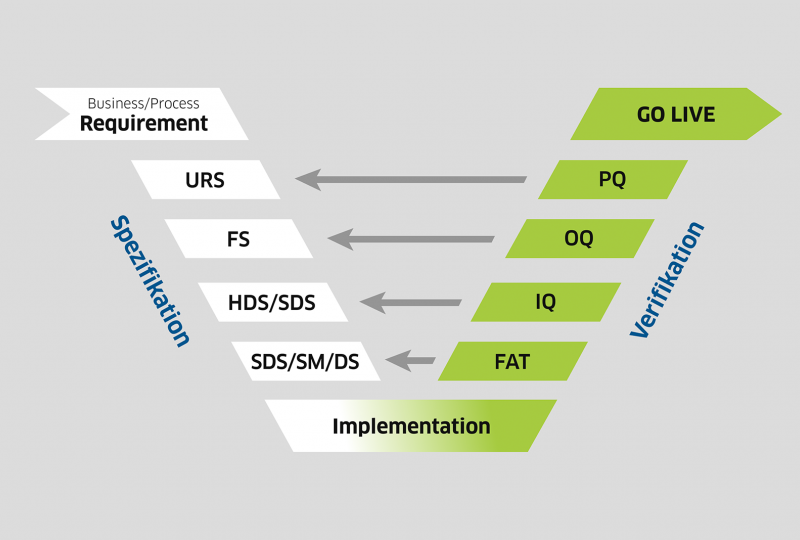

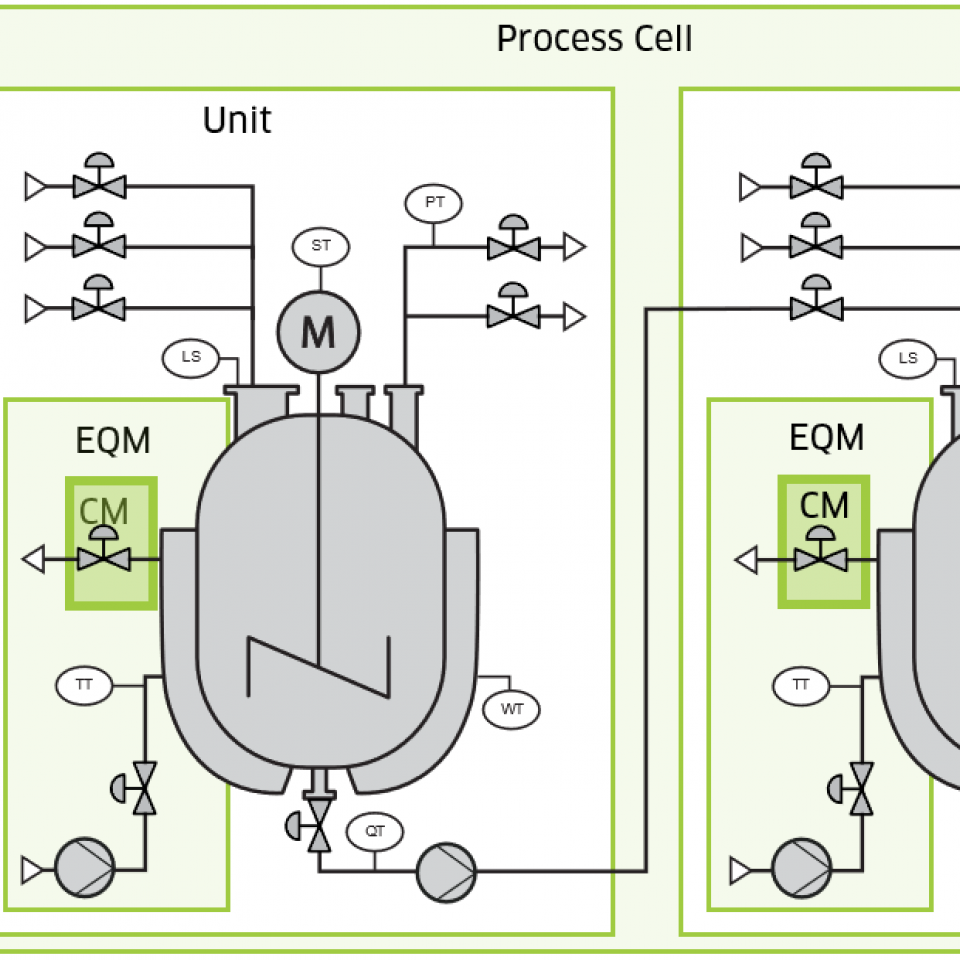

Production processes must be reliable, flexible and quickly adaptable. With ControlTech Engineering AG (CTE), you receive a tried and tested automation strategy that makes your systems more efficient, safer and future-proof - implemented with a modular, system-neutral approach in accordance with international standards such as ISA-88.

Your advantages at a glance

We use standardized modules to significantly reduce your project runtimes.

Proven automation concepts minimize downtimes.

Our solutions fit perfectly into existing systems - regardless of the platform.

We speak your language. Close cooperation is at the forefront of all CTE projects. For us, knowledge transfer at eye level and cost transparency are part of a long-term partnership. Our modular approach optimizes your production processes, avoids complexity and ensures clear, consistent communication - from planning to handover. You benefit from sustainable results that really work.

Simple, modular, efficient - up and running!

Read more

Our building blocks for your automation:

Engineering & hardware planning - well thought out and structured

Project support: programming & integration - reliable and precise

Industrial IT & data management - secure and scalable solutions

Production Recipes - Flexibly controlled for reliable processes

Monitoring systems - clear overview of buildings, rooms and equipment

Why CTE is the right choice:

Our automation solutions are consistently designed for efficiency, flexibility and reliability. Together, we design your processes to be modular, scalable and future-proof.

Our solutions are based on the international ISA-88 standard. This enables:

Comprehensive process monitoring: From individual components to the entire plant

Modularity: Reusable modules for process control and integration

Flexibility: Adaptation to new requirements without major interventions

Fast implementation: Standardized approach shortens project durations

The increasing demand from our customers has prompted us to formulate a common language.