Siemens PCS neo upgrade at the FHNW

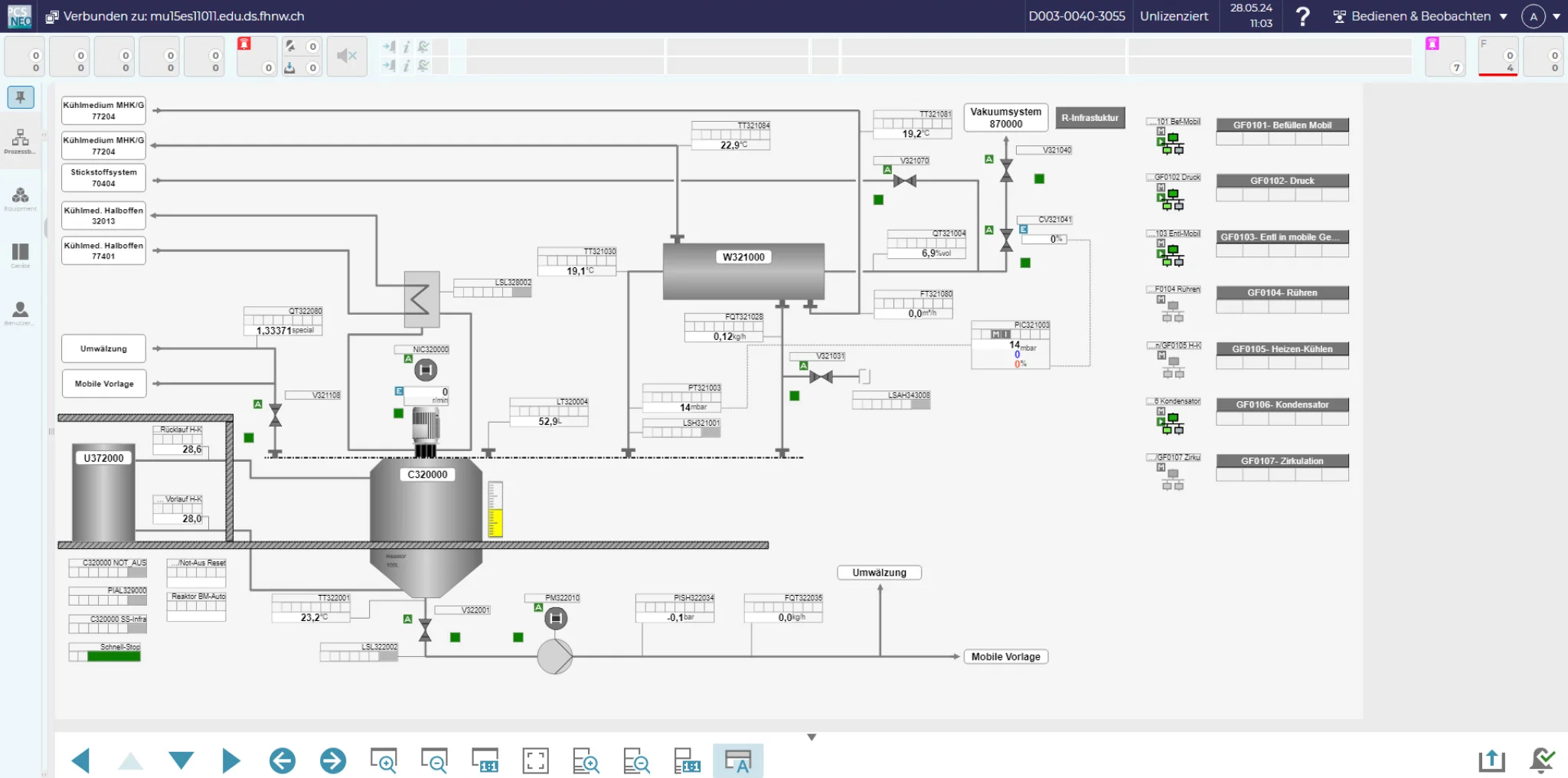

How a comprehensive upgrade of the PCS neo system at a plant at the Process Technology Center (PTC) of the University of Applied Sciences and Arts Northwestern Switzerland (FHNW) in Muttenz in collaboration with Siemens not only solves existing problems, but also ensures long-term operability.

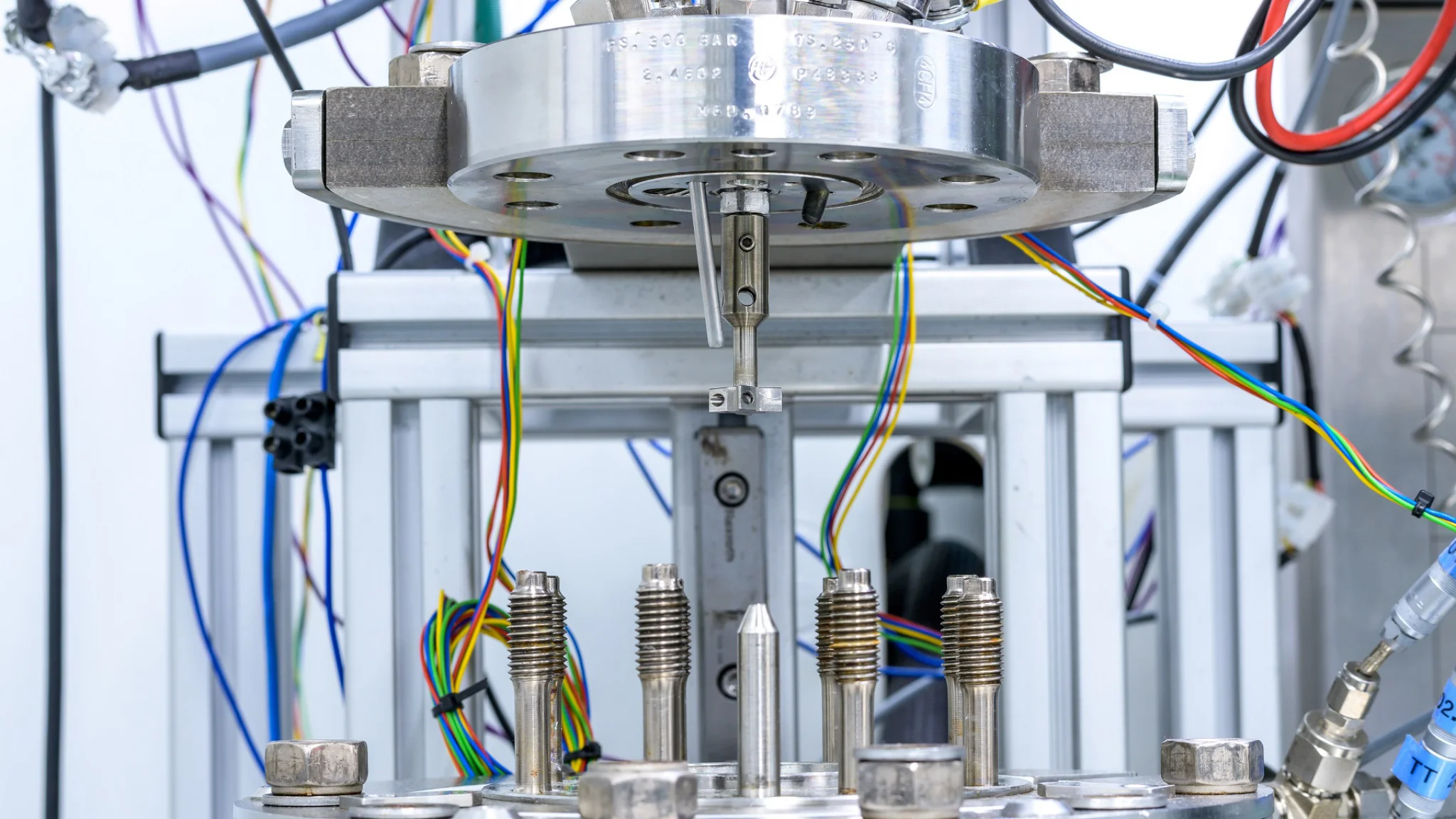

With its Process Technology Center (PTC), the University of Applied Sciences Northwestern Switzerland (FHNW) in Muttenz offers one of the most modern infrastructures in Europe in the field of life sciences. This provides students with practice-oriented training and further education. In 2020, ControlTech Engineering AG (CTE) equipped the PTC's reactor and solvent storage facility with the Siemens PCS neo process control system. Four years later, a comprehensive system upgrade is required to ensure long-term operability.

In cooperation with Siemens and CTE, the FHNW decides to comprehensively modernize the PCS neo system. This step should also ensure the long-term operability and efficiency of the system. An upgrade would also add important new functions to PCS neo. For example, the configuration of interfaces to standard-compliant field devices such as remote I/Os, frequency converters and package units, which in V3.0 still had to be implemented via a PCS7 coupling CPU. When the plant was equipped with PCS neo, the system was still at an early stage of development. No other realization was possible at that time. Four years later, however, the initial situation looks different.

System upgrade with challenges during commissioning

In addition to the PCS neo upgrade, the VM server firmware was also updated. Based on this, CTE set up the PCS neo system from scratch, while at the same time Siemens upgraded the PCS neo project to version 4.1. Despite careful preparation, problems arose during commissioning - particularly with the connection to the external systems. However, the difficulties were quickly identified, corrected together with Siemens and successfully tested. An important innovation in the PCS neo system is the use of "device types" for the connection to third-party devices, which significantly simplifies the integration and use of third-party devices.

Early risk analysis and regular communication at project management level ensure success!

"Although it was a comparatively small project, we followed the standard CTE process," explains project manager Ronny Wasmer looking back. The kick-off meeting at the beginning of the project with all those involved from CTE, Siemens and FHNW ensured understanding on all sides. "This meant that decisions could be made quickly during commissioning." Discussions about all relevant tasks and project risks were already important at this stage. Despite the challenges and the brief halt during commissioning, the FHNW PCS neo project was successfully completed: "We had to check the exact configuration of the interfaces together with Siemens, but with the knowledge gained from this we were ultimately able to successfully integrate and test all third-party systems in PCS neo again . Because precisely such a scenario had already been identified as a project risk and measures had been recorded," adds Ronny Wasmer. The early risk analysis and regular communication at project management level were crucial.

Thanks to the promising adaptation of the PCS neo system, the FHNW can continue to offer practice-oriented training in the field of life sciences. This project demonstrates the importance of close collaboration and careful planning in technologically demanding projects. The implementation has made the system operational again and expanded internal expertise in the use of PCS neo, which will benefit future projects.