Development of a demo system for MTP with PCS neo

How can the MTP standard be implemented in practice? As part of his bachelor's thesis, our system engineer Eric Borer developed a demo system based on PCS neo. It not only shows the current status of implementation of the MTP standard, but also serves as the basis for a production-ready system.

The demands on the process industry are currently changing rapidly. Markets are becoming more dynamic, products more diverse and innovation cycles ever shorter. As a result, operators of production plants are under increasing pressure to make their processes more flexible and at the same time more economical. Traditional automation systems are increasingly reaching their limits. Changes are often complex, time-consuming and associated with high costs.

One promising approach to overcoming these challenges is the standardization of modular automation. Systems are no longer viewed as a rigid overall system, but are instead composed of reusable functional units. These modules have their own intelligence and can be flexibly replaced or expanded as required.

Modular process automation with MTP

The key to this approach is the Module Type Package (MTP). This industry standard in accordance with VDI/VDE/NAMUR 2658 defines how modules describe their services, interfaces and visualizations.

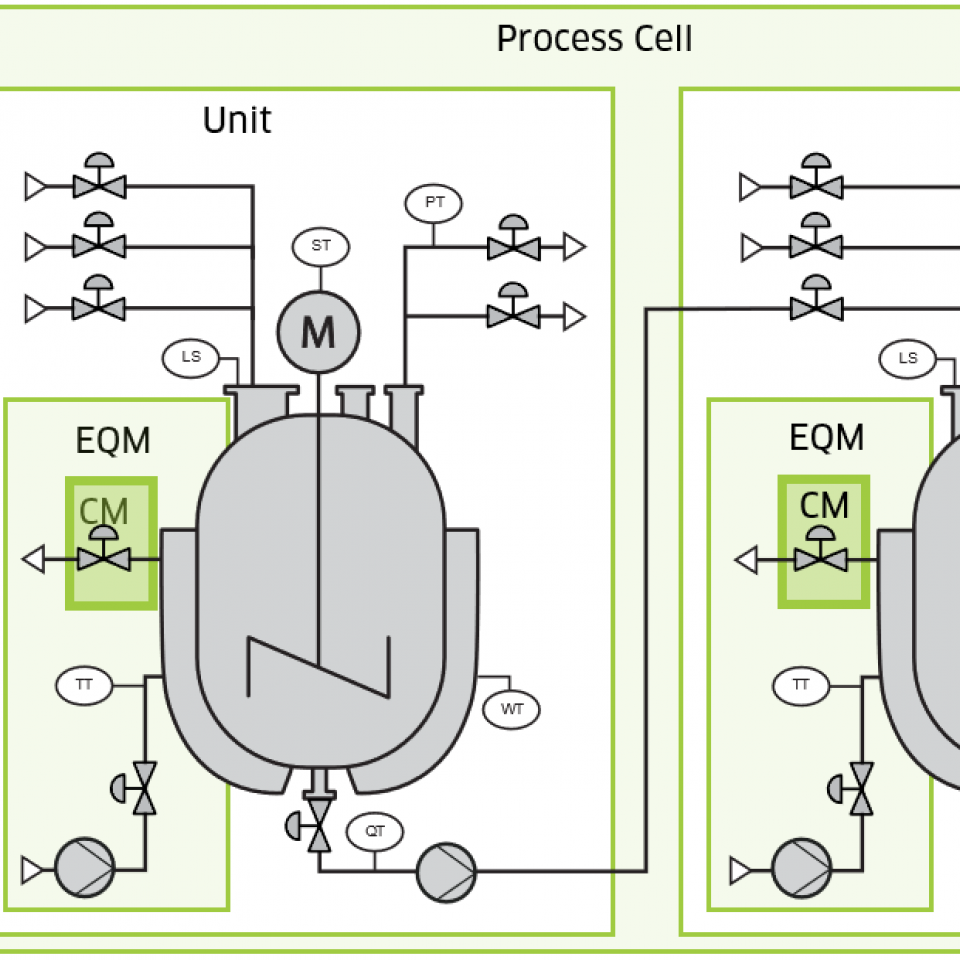

This means they can be integrated into a higher-level control system, the so-called Process Orchestration Layer (POL), with minimal engineering effort and controlled centrally from there. The POL orchestrates the modules, provides standardized user interfaces and enables recipe-based control of complete processes. For operators, this means less integration effort, shorter project runtimes and significantly more flexibility in the event of changing production requirements. This makes MTP a crucial building block for the future of the process industry and a practical tool for turning the vision of "Plug & Produce" into reality.

What does the practical implementation of the standard look like?

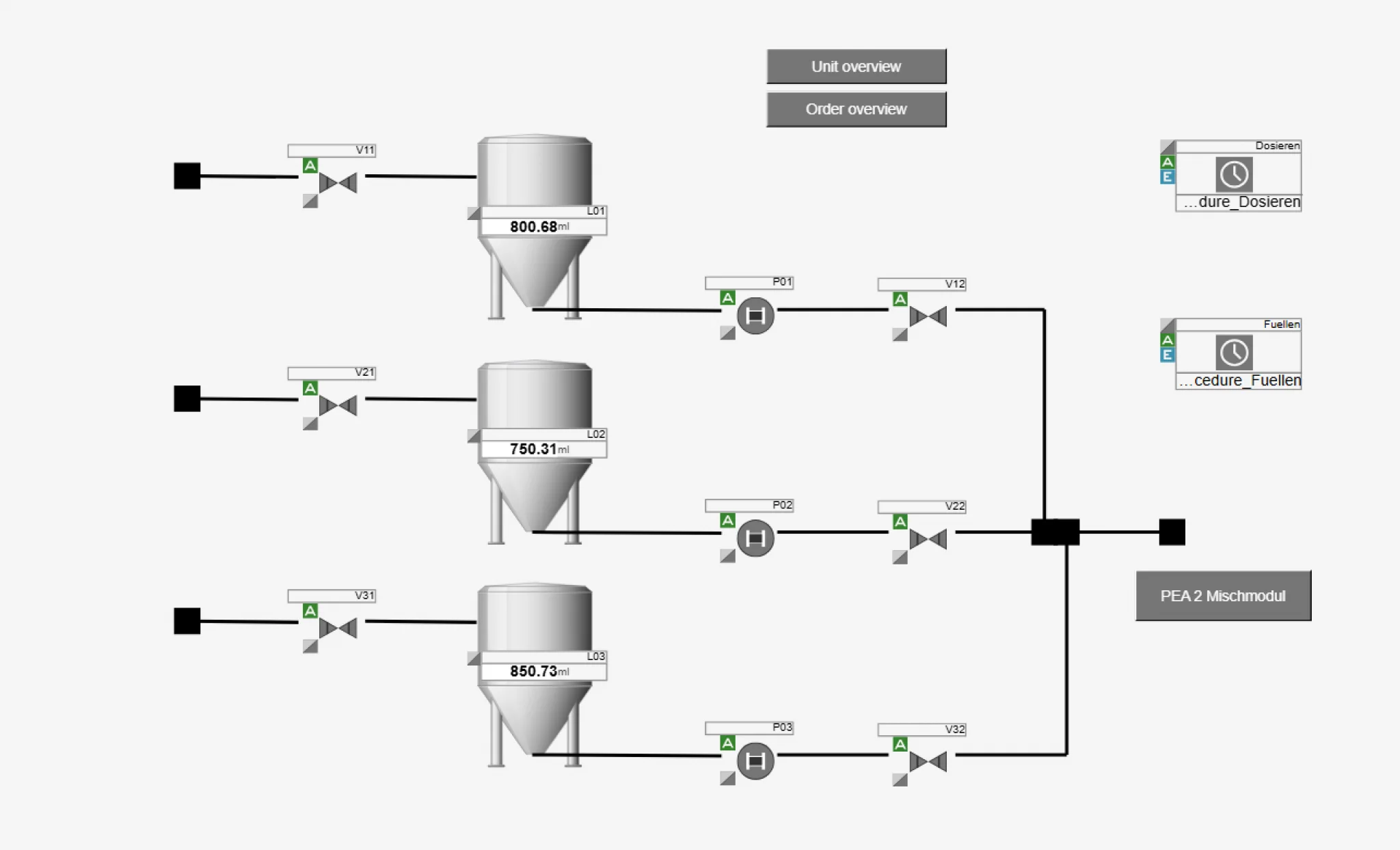

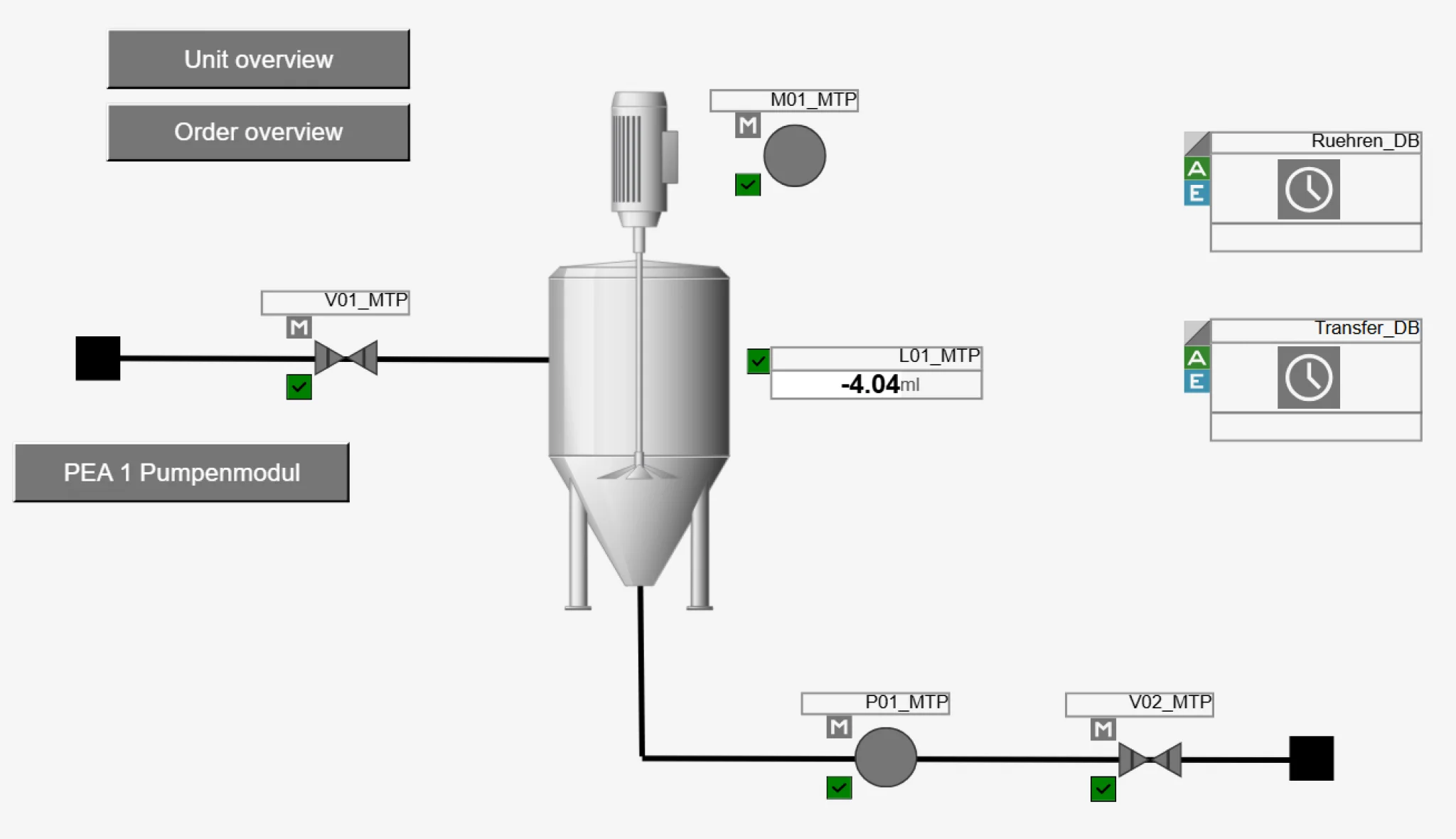

As part of my bachelor's thesis, I developed a system that demonstrates the MTP standard in conjunction with the PCS neo process control system from Siemens. The aim was to develop a modular process plant that demonstrates the integration of process equipment assemblies (PEA) from different manufacturers in the process orchestration layer (POL).