Automation of production lines for pharmaceutical companies

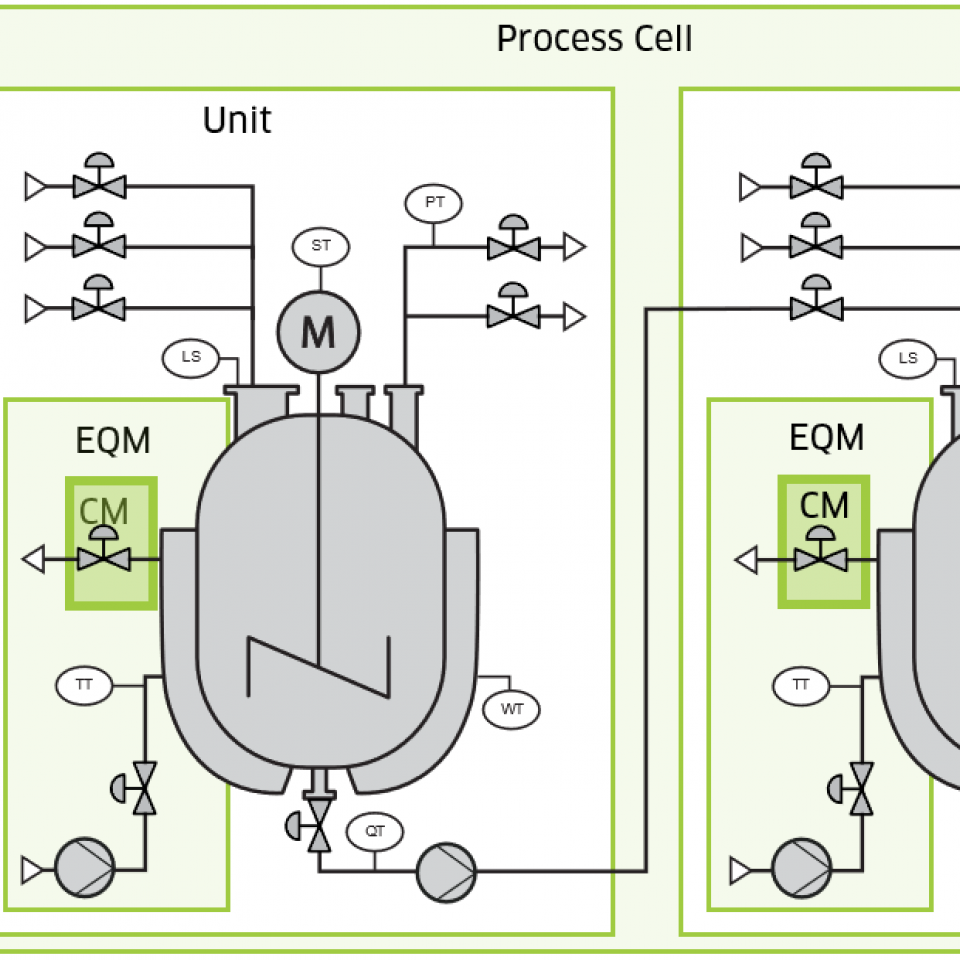

Package units can be used to assemble a production system according to the plug-and-play principle. ControlTech Engineering was commissioned to connect a new package unit to the existing DeltaV building management system. It was actually quite simple, but we had to dig deep into our bag of tricks to define the right procedure.

Our experts automated a production line for an international pharmaceutical company and simultaneously connected the package units to the building management system. The package units had already been defined, CTE was responsible for describing the interfaces and implementing them.

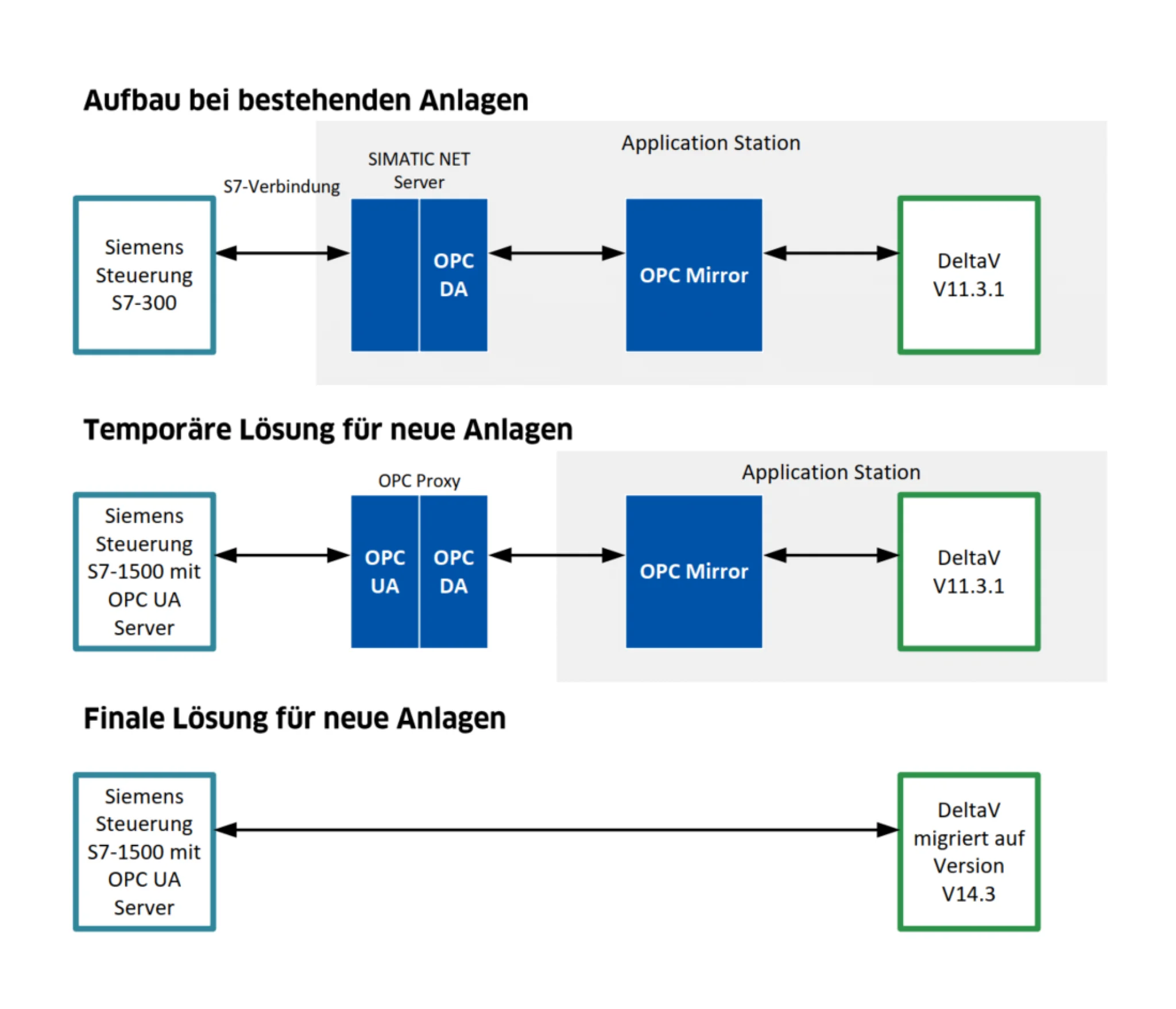

In principle, this procedure is unproblematic. The CTE only needed to connect several new package units to the existing DeltaV building management system (GLS). The systems were to be connected via the OPC UA communication protocol in accordance with the customer's specifications. As the original version of the building management system was not yet capable of communicating via OPC UA, an upgrade had to be carried out. Two weeks were available as a time window, but unfortunately the upgrade could not be carried out. Due to time pressure and uncertainty, an alternative solution had to be found quickly so that the new package units could still be connected to the existing building management system.

Routine becomes emergency

A simple connection to the package units turned into an emergency. Innovative solutions had to be found quickly, otherwise the project could have been delayed. Together with the customer, the idea was born to convert the OPC UA communication protocol into OPC DA using a Kepware server. An additional server was required for the implementation. But these delivery times were too long for the emergency situation. The project team had to find other options quickly. CTE did not hesitate and provided one of their servers. As an emergency solution to ensure that the system would function 100% at all times. But this is not a long-term solution. It's inconvenient to have an additional server in the system. It can fail and interrupt communication. A situation that must be prevented by all means. The conclusion is correspondingly ambivalent: The final solution works, but it is still important to optimize it promptly. Even if our experts have made the best of the emergency situation and the system is running.

Solution-oriented to the goal

This example shows how pragmatic and solution-oriented CTE's approach is. As an owner-managed company, CTE stands for commitment and partnership at all times. These are not just empty words, they are genuine corporate values. Even if the emergency solution appears risky, the specialists at CTE have found a way to prevent the worst-case scenario. The initial situation was nothing out of the ordinary. But the emergency solution required flexibility and quick decision-making processes. Thanks to its organizational structure, CTE has flat hierarchies and employees can really make a difference. That's why our customer is also satisfied: "We would order from CTE again at any time. The employees are reliable and work to a high standard. The close cooperation and exchange were very helpful."