Powder Handling 4.0

CTE has been working successfully for CABB Pratteln for many years in the area of automation with DeltaV from Emerson. However, the acquisition of mobile entry systems for use in various control systems presented us with new challenges. An innovative solution had to be developed.

Last year, two new powder application systems with a mobile design were ordered. In an initial project meeting, it was decided that these systems with wheels should be used in different parts of the plant. However, different control systems in use in the individual parts of the plant were between six (DeltaV) and twenty years old (Schneider control systems), which led to the question: 'And how should these new powder application systems be controlled?'

Innovative Solution

Previous practice was to program a new basic function when a new type of entry system was purchased. However, this had the disadvantage that basic functions, phases and screens had to be adapted in the affected units. This regularly meant that the recipes created for the corresponding unit were no longer usable. Because more time was available this time, there was an opportunity to develop and implement a better solution.

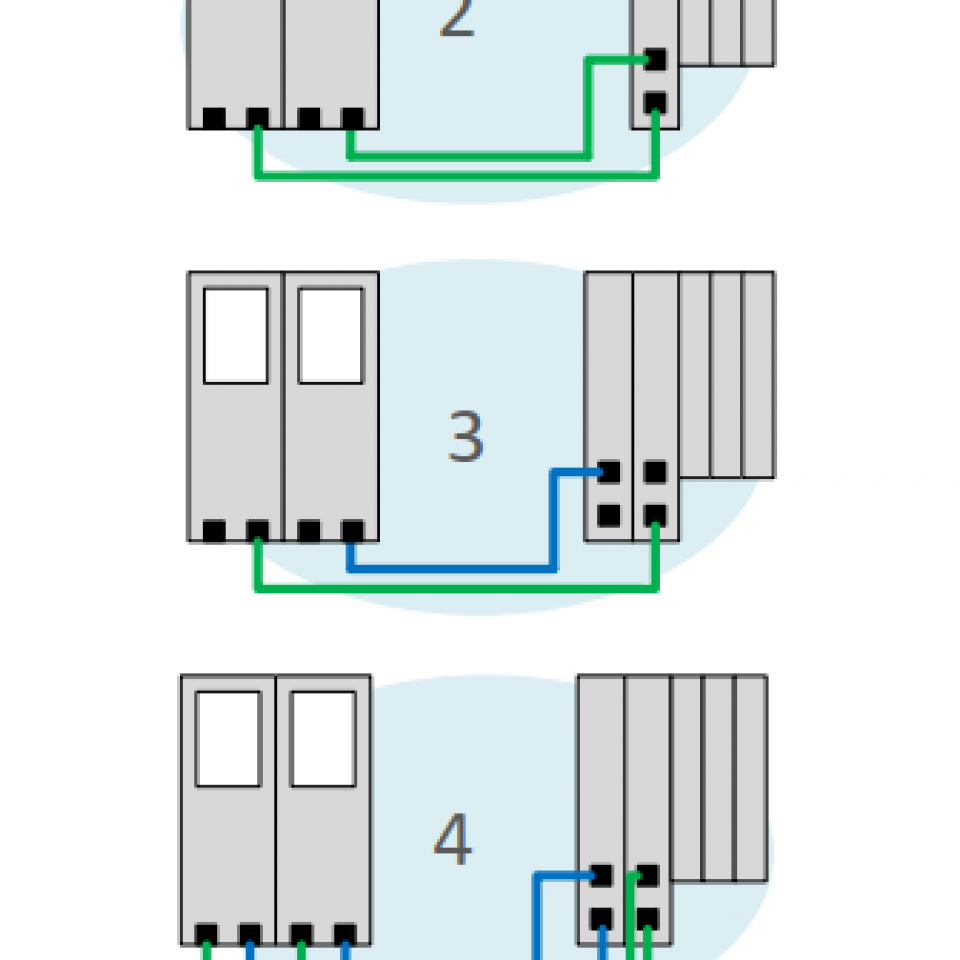

This solution provides for the pneumatic control of the docking station (supplied by Rubitec) and the control of the Powder Transport System (PTS), controlled by DeltaV, to be separated. The connection to the control system is made using CHARM-IO controllers, combined with CHARM valve terminals, in a mobile control box ordered directly from Emerson. As a result, wherever the PTS system is to be used, only electrical, air, nitrogen and vacuum connections and two network cables need to be installed.

As soon as the control box and with it, the CHARM-IO controller (CIOC) are supplied with power, the CIOC logs on to the DeltaV system and takes over control of the powder application system. If the CHARM-IO controller is not connected, all alarms of the affected IO are automatically suppressed. In this way, the solid material input of a reactor is separated: Into a fixed standard discharge chute, which runs under the ceiling up to the reactor (basic functions, phases and images always remain the same), and an exchangeable part above the ceiling, which as an infrastructure assembly fits flexibly for all reactors and all control systems

Also Applicable for Older Control Systems

The infrastructure part is controlled using a recipe from DeltaV. Only two (digital) signals are responsible for communication with the underlying reactor, which are used to query via external referencing whether the solid material valve of the reactor is open (release for feeding) and whether the manual button for closing the solid material valve of the reactor has been pressed (completion of the feeding sequence). These signals can also originate from older control systems, meaning that the new powder feed systems can also be used for older control systems.

In this way, CABB Pratteln saves time and money with every product change and the associated adjustment of the solid material feed system.