Simatic PCS7 V9.1 In Practice

The new Simatic PCS7 version from Siemens offers the option of using Control Module Types (CMT) and Equipment Module Types (EMT). But what do these terms stand for? And how is the new version proving itself in practice? CTE was able to successfully implement the use of CMT and EMT in a project for a pharmaceutical company.

The customer from the pharmaceutical industry operates four identical small systems that are designed for mixing patient-specific cancer drugs. Each system has its own operating station and is to be used in the clean room. CTE was commissioned to program the control systems of these plants with the latest Simatic PCS7 version. To implement these requirements, the customer wanted to use the new option of class-based EMT and CMT objects.

What do CMT and EMT stand for?

CMT is the abbreviation for Control Module Type. EMT is the abbreviation for Equipment Module Type. Since version 8 of Simatic PCS7, it has been possible to create CMTs and instantiate them.

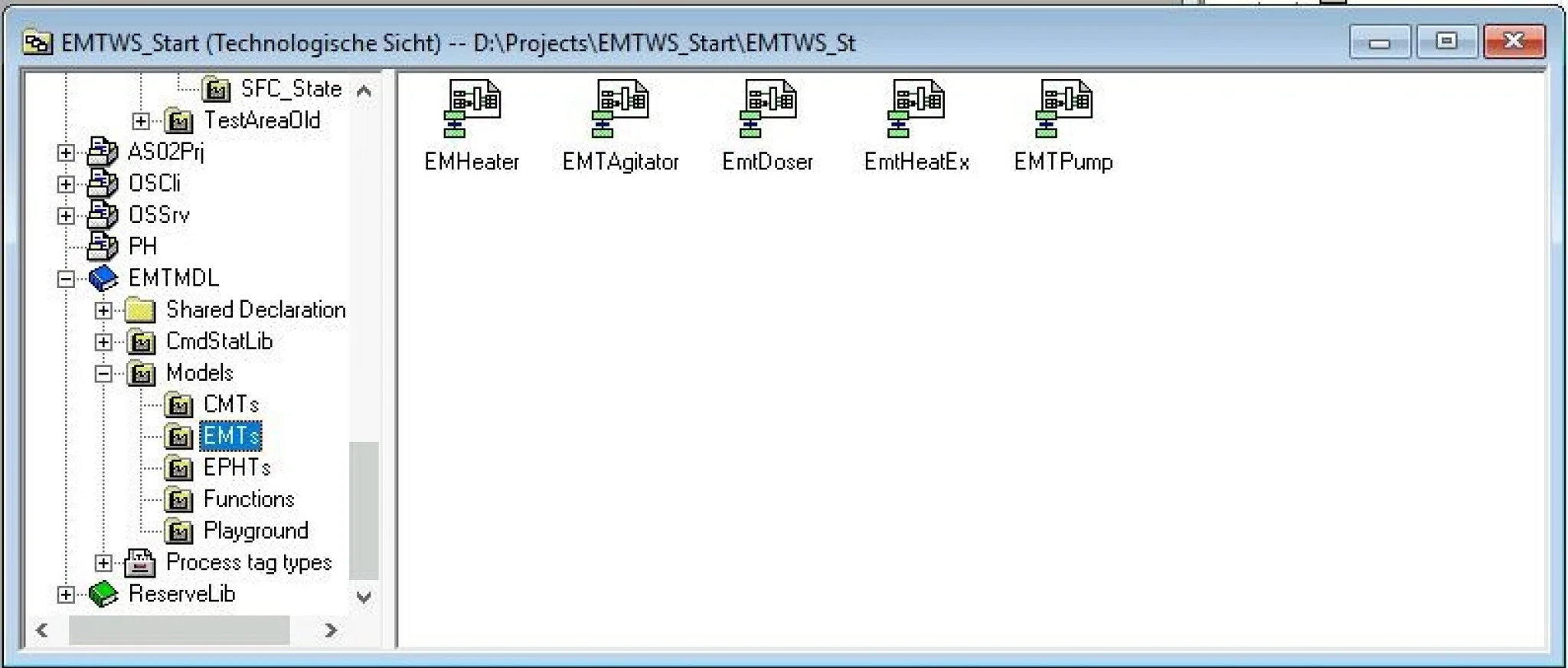

Version 9.1 now also applies the type-instance concept to EMT. Standardised engineering can be achieved through the consistent use of CMT and also EMT. The CMT template and the EMT template created in the library can be instantiated later in the project.

CMT

Only basic modules such as valve or motor modules are used in a CMT. Only one basic module is used in this combination of standard Siemens modules. This makes it easier to work with the EMT.

Options can also be used. By defining optional blocks in CMTs, a large number of different variants of this CMT can be instantiated in the project. One variant is available, for example, for a display measuring point for the 420 mA input signal or PA field device.

Through the technological I/O interfaces, parameters and connections which can later be modified in the instance are assigned. This could, for example, be a range and unit of an analog input signal, such as 0 ... 170 °C, at one measurement point, while at another measurement point it may be -1000 ... 2500 mbar.

EMT

In an Equipment Module Type, the basic functions are implemented, such as pressure control or stirring. Part of the technical setup is a sequence control with the SFC type. Operating modes, setpoints, other parameters and the actual sequence control with the sequence chains are defined in the sequence control. In addition, the SFC type supports extended features of SIMATIC BATCH.

An equipment module always controls actuators and sensors with the help of step chains. This means that subordinate individual control units (control module types) are assigned to an EMT or are controlled by it. In terms of hierarchy, the EMT is above the CMTs. The changeable parameters or switchable connections are also defined in the technological I/O interface of the EMTs.

Instantiate and synchronise

Once the CMTs and EMTs have been defined and programmed in the library, they can be instantiated. Various tools are available for small and large projects. For example, all parameters from the technical I/O interface can be entered in a list view, allowing a large number of valves, motors or analog inputs to be created quickly. The same instantiation function is also available for the EMTs.

If a change occurs in a CMT or EMT, the PCS7 has an adjustment function. This function can be used for a project. All instances and detected changes between type and instance are displayed in the file transfer dialog. The user can deselect the differences that are not to be synchronised. With just a few clicks, all changes are imported and don't have to be laboriously corrected by hand.

Use in Practice

The CMTs for all four systems were instantiated for the programming of the control systems at our customer's premises in the pharmaceutical sector. The main work was to create the EMT with the SFC type as a batch interface. The process screens for the user interface were automatically created with the components used and arranged accordingly.

The implementation has shown that the number of CMTs with options can be kept small with the use of PCS7 V9.1. In practice, there is now only one valve CMT for all valve variants. When using the CMTs and EMTs, the advantage of synchronising the instances has also proved very useful. After a change in the EMT, this could be rolled out to all instances with just a few clicks and the customer was able to continue testing immediately. The project was successfully completed and we gained valuable knowledge for the future use of CMT and EMT.