Automation of complex workflows - the path to new productivity

Robots have been an integral part of many manufacturing industries for decades. However, industrial production is currently undergoing a profound change towards even greater efficiency. Concepts such as the unified namespace or MTP enable new levels of efficiency, flexibility and quality. They are driving the merging of previously isolated processes into fully automated workflows. At the same time, connectivity is improving so that relevant data is available securely at any time and from any location. These developments are part of the much-discussed fourth industrial revolution - Industry 4.0 - which integrates digital, biological and physical systems into a new whole and fundamentally changes the way we produce.

Shaping a smarter future

Automation and robotics are at the heart of this transformation. In Switzerland, they were first introduced in the watchmaking industry and other areas of precision mechanics before expanding to applications with extremely high precision requirements. Today, numerous sectors - from the pharmaceutical industry to medical technology and transportation - benefit from the advantages of automated systems. These not only enable more consistent production processes with less downtime, but also round-the-clock production. In addition, machines often perform repetitive tasks more precisely than humans, which increases product quality and reduces costs at the same time.

Another advantage: automation reduces hazards in production by taking over dangerous or physically demanding tasks. In addition, automated documentation and process reliability also increase product conformity - a decisive factor in highly regulated industries.

"Of course, automation is often aimed at repetitive tasks - but that's not always the main goal," explains Dominic Brunner, CEO of ControlTech Engineering (CTE), an engineering firm specializing in industrial IT and automation in Liestal near Basel.

"In the pharmaceutical and biotech industry, the most important thing is that every step, every batch and every process is precisely reproducible and fully documented. Automation is the key to achieving these goals - for greater compliance and higher product quality."

New tasks for robots

Although companies have been using certain automation options for decades, there has recently been a clear trend towards more comprehensive automation of entire areas of work. Robots are now taking on increasingly complex tasks.

"Our customers come with very different requirements - from the automation of individual work tables to complete buildings," says Alain Farine, Business Development Manager at JAG Jakob, a Swiss company based in Jura that specializes in process systems and automation solutions.

He explains: "In the pharmaceutical and biotech industry, there are typically three separate functional areas: Research & Development, Production and Quality Control. In the past, it was usually only possible to connect them by manual handovers - a time-consuming and error-prone process. Today, mobile robots can bridge these gaps by moving independently between departments and even floors. This type of building automation is gaining in importance and was recently successfully implemented by us at a leading pharmaceutical company in the Basel region."

Rethinking jobs - from elimination to added value

Automation is often associated with job losses. However, the reality is more nuanced: it creates space for new tasks in which human expertise is utilized to a greater extent.

"Automation does not necessarily mean replacing people," emphasizes Farine. "Rather, we enable them to control, train and optimize robots - and thus use their knowledge in an even more targeted way."

Especially in highly specialized areas such as medical technology or biotechnology, where there is a global shortage of skilled workers, automation can be a decisive lever.

„Einige unserer Kunden berichten, dass ihre Produktionskapazität nicht durch Maschinen oder Marktgrenzen limitiert ist, sondern durch den Mangel an qualifiziertem Personal. Intelligente, benutzerfreundliche Automatisierung kann hier einen echten Unterschied machen.“

Flexible systems for dynamic requirements

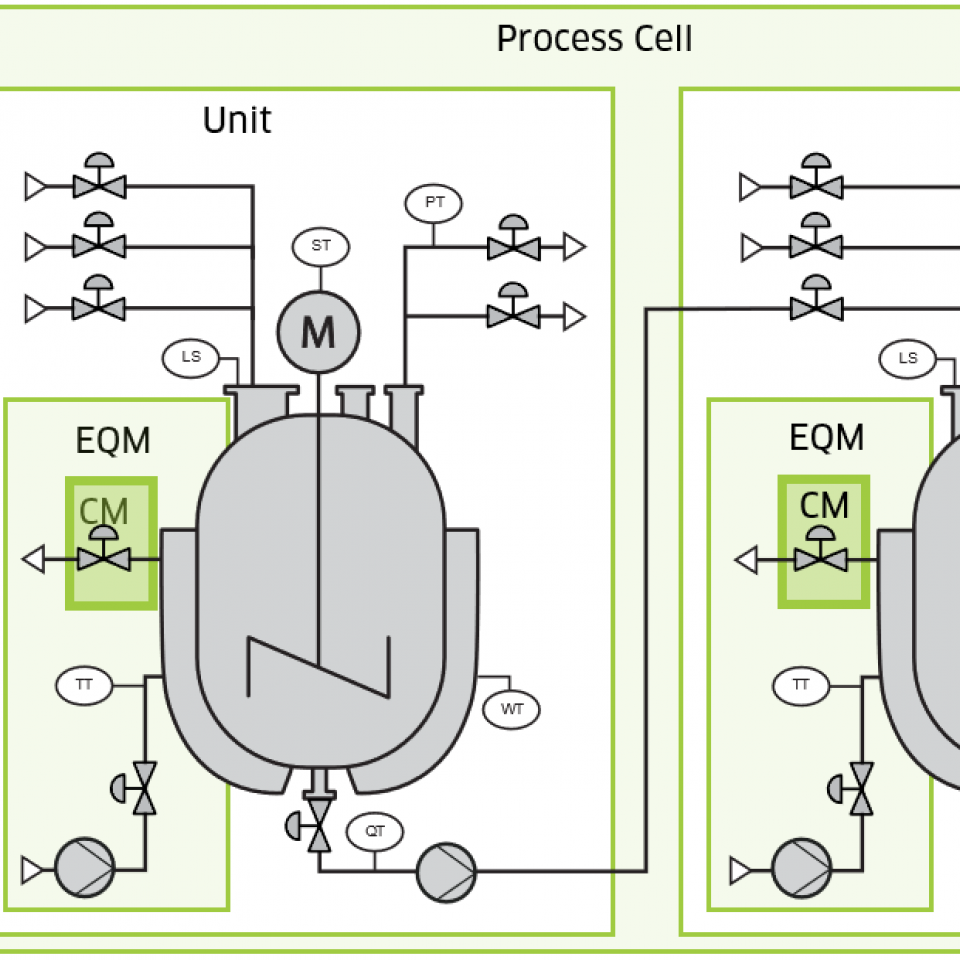

In pharmaceutical production, too, there is growing pressure to implement modular systems in order to be able to react flexibly to changing product portfolios and market demands. Automation enables faster changeovers between processes, optimizes the use of resources and saves space. This also applies to research laboratories, where modular setups facilitate rapid adaptations to new experiments and technologies.

One promising approach is the Modular Type Package (MTP) - an open standard for modular automation that is the subject of much discussion, particularly in the Basel region.

"The proximity to innovative companies with a long-term investment horizon makes Basel an ideal environment," says Brunner. "A leading pharmaceutical company approached us with the desire to explore the advantages of MTP. Together, we developed a pilot project based on an existing proof of concept. The findings confirm the potential - MTP will play a central role in process automation in the future."

Networking data intelligently - with the unified namespace

Another key topic is the unified namespace - a universally accessible, structured data repository that centralizes all of a company's real-time data. It is a key element for networked Industry 4.0 solutions and an important driver for the Industrial Internet of Things (IIoT).

"The Unified Namespace ensures that all relevant data is accessible regardless of location and system. It forms the basis for the FAIR principles of data - i.e. that it is findable, accessible, interoperable and reusable. This data integrity is particularly important in regulated industries."

Conclusion

Today, automation is far more than just a means of increasing efficiency. It is a strategic tool for redesigning business processes, overcoming personnel bottlenecks and meeting regulatory requirements. Modular systems, digital standards such as MTP and concepts such as the Unified Namespace are creating new perspectives for the networked production of the future.

The Basel region plays a key role here: as a hotspot for pharma, biotech and industrial innovation, it offers ideal conditions for setting global standards for intelligent automation technologies.