Watch out - WinMOD is here!

CTE is now using WinMOD not only for simple IO simulations, but also for more complex process simulations, which enable, for example, the testing of system recipes or the training of employees. Our customer from the pharmaceutical industry has already benefited from the advantages.

Process simulations are not yet being welcomed by all customers in the industry. This is mainly due to the widespread opinion that they are not needed. However, we can counter this view with some weighty arguments.

One of our customers, a renowned pharmaceutical company in the Basel area, experienced that process simulations can play an important role when it comes to increasing the profitability of a plant and turnover. Delays in the construction of a plant meant that it had to be put into operation twice. This was because the MES system was completed later than planned. In order to commission the plant with the MES system and thus merge around 14,000 IOs in one month, the automation software had to be of a particularly high quality. The effort involved in the SAT had to be minimized. It was therefore essential to test the software prior to commissioning. We therefore received the order to build a simulation, with LabVIEW providing a simple and practical solution to create and successfully implement a process simulation on time.

However, the high time requirements for commissioning were not the only reason for placing the order. In addition, due to the high complexity of the system, there was a need to test the system recipes and train the employees. By testing the recipes, it was possible to eliminate the most significant errors and to simplify or shorten their introduction by training the employees.

This example shows that the benefits of a simulation are not limited to a specific application. Rather, simulation can repeatedly offer positive partial benefits over the entire service life, from conceptual design to the decommissioning or refurbishment of a plant:

Recognizing design errors at an early stage of development

Reduction of dependencies in planning and therefore greater planning security

Accelerating the production and testing of automation software

Testing of software changes and increased security during their implementation

Setting and parameterizing the automation software

Reducing the burden on employees

Efficient virtual commissioning

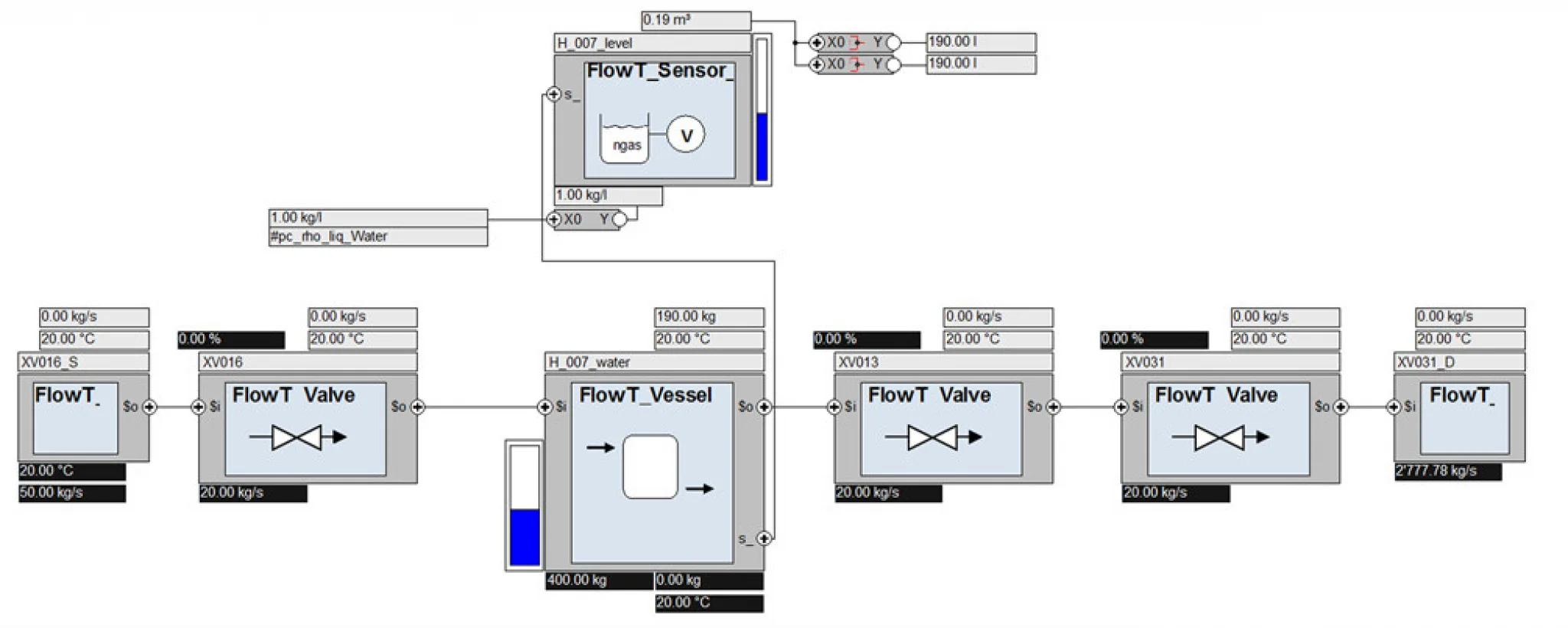

With WinMOD, we have brought a technology into our company that allows us to create process simulations in line with requirements and with a considerable time advantage over the conventional method (LabVIEW) thanks to tools for the automated creation of process simulations and prefabricated function blocks. According to the current state of development, complex infrastructure for connecting the simulation to the automation system is a thing of the past, also due to the implementation of the OPC standard. WinMOD's development with regard to automated engineering is moving in the direction of generating process simulations directly from the P&ID. A Comos interface, which also generates a model based on the system planning, is thus developing from a vague fantasy into a tangible idea.

As we at CTE also want to stay up to date in this area of automation , we are stepping up our efforts and upgrading our infrastructure so that we can offer our customers process simulations in line with their ideas and requirements. Our aim is to make simulation as easy as possible for our customers to use and to develop attractive offers for this purpose. To achieve this, we rely on a centralized infrastructure, which the customer can access remotely if required.