A Next-Generation Digitalised Facility

Pharmaceutical company F. Hoffmann-La Roche AG has set itself ambitious goals in the planning of a new research facility (Building 98) in Basel. These entail high demands in terms of the flexible arrangement and dynamic composition of the individual rooms. The idea is for the rooms to be equipped with different, individual functions for each series of experiments. This requires an unprecedented level of automation for building technology.

It goes without saying that the ambitious goals also required new approaches. As these could not be achieved through conventional methods and systems, the pharmaceutical company F. Hoffmann-La Roche AG decided on a combination of something new and a proven systems with a new concept (OSIsoft PI). CTE is proud to have been actively involved as an OSIsoft PI system integrator and now also as a reseller, thus contributing to the success of this flagship project.

Modular structure of individual zones

For the automation of the building technology, each floor was divided into so-called zones, each with a defined set of connections (water, air, exhaust air, etc.) and sensors that are consistently mounted on the ceiling. This allows the partition walls to be moved according to requirements and the rooms to be enlarged or reduced in size. Such a set of zones is then joined together to form a "module".

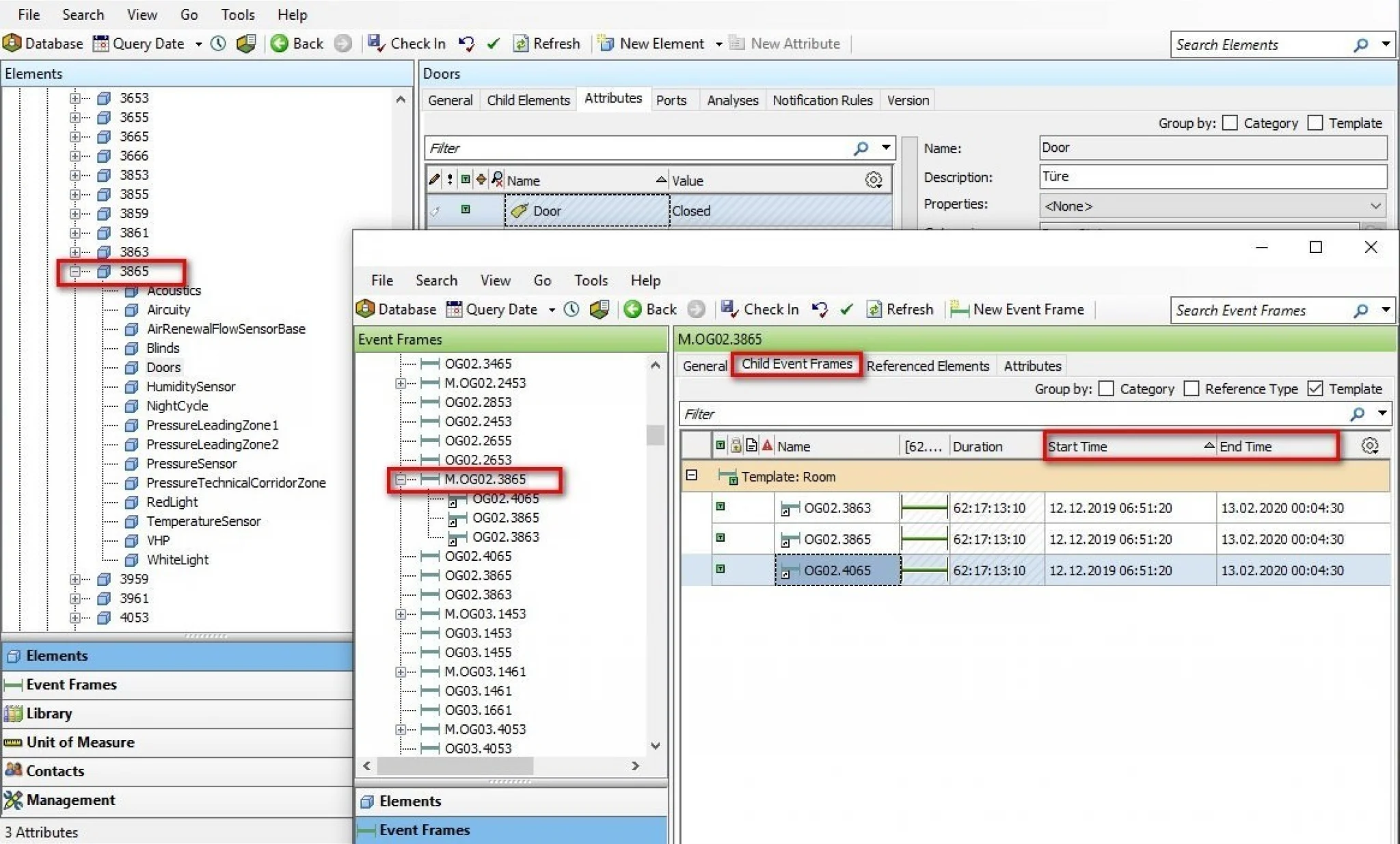

So that this flexibility can also be mapped in the monitoring system and the collected data can always be assigned to the current room configurations (also retrospectively), the individual floors and the associated zones, including the permanently installed and mobile process systems, were mapped in the OSI Soft Asset Framework (AF) server. The concept provides for the modular structure of the individual zones and the current and retroactively identifiable affiliation of these zones to be implemented in the PI system with "event frames". This means that when a new "module" is created, "RIBIS" creates a new event frame via the OSI Soft WEB-API, adds all associated zones to it and sets the start and end date of the module.

Analysis and notification services were used for the analysis, monitoring and notification of various actuators. Depending on the configuration, groups or individual employees are notified by email in the event of problems.

Flexible automation concept for the construction phase

Knowing that we would have to expect adjustments and additions to the automation of the building technology and therefore also to the AF structure over the entire duration of the project, we created an "Automated Engineering" concept from the outset. The concept is based on a combination of automatically generated Excel lists and the subsequent import into the monitoring system with the existing OnBoard tools.

For this reason, we wrote a C# application that reads the relevant BACNet information from a csv file and creates an Excel tag list from it. We were then able to import this into the OSI PI Data Archive Server using the Excel add-in "PI-Builder". The import files for creating the individual zones in the AF structure were also generated from the identical csv file. These Excel files were also imported into the AF server using the "PI-Builder" add-in.

By taking the approach of automatically creating an Excel template and using OnBoard tools to import it into the monitoring system, we have delegated the responsibility for properly creating the required objects to the monitoring system.

Conclusion

Thanks to our know-how in various programming languages (C#, Phyton, etc.) and the available OnBoard resources, we were ideally equipped to connect all the desired "components" to the monitoring system, as well as to check automatisms and document the resulting outcomes. CTE was thus able to consistently pursue and implement the ambitious goals of F. Hoffmann-La Roche AG with regard to the automation of building technology.