Chocolate Job for CTE

With Pronatec, CTE was able to acquire another customer from the food industry and support them in setting up a new plant. The company processes organic and Fairtrade-certified cocoa beans into high-quality cocoa mass, cocoa butter and cocoa powder. We supported the project with our advice, concepts and products in the area of OT infrastructure. We currently manage the entire life cycle of the solutions used and provide support through regular maintenance and the necessary on-call service.

When we first inspected the Pronatec production site near Schaffhausen am Rheinfall, we found a huge empty hall. It's where, at the start of the new project, an inspection and initial discussions took place, so that we could begin with the conceptual design phase.

Efficiency Resulting From Standardised Concepts

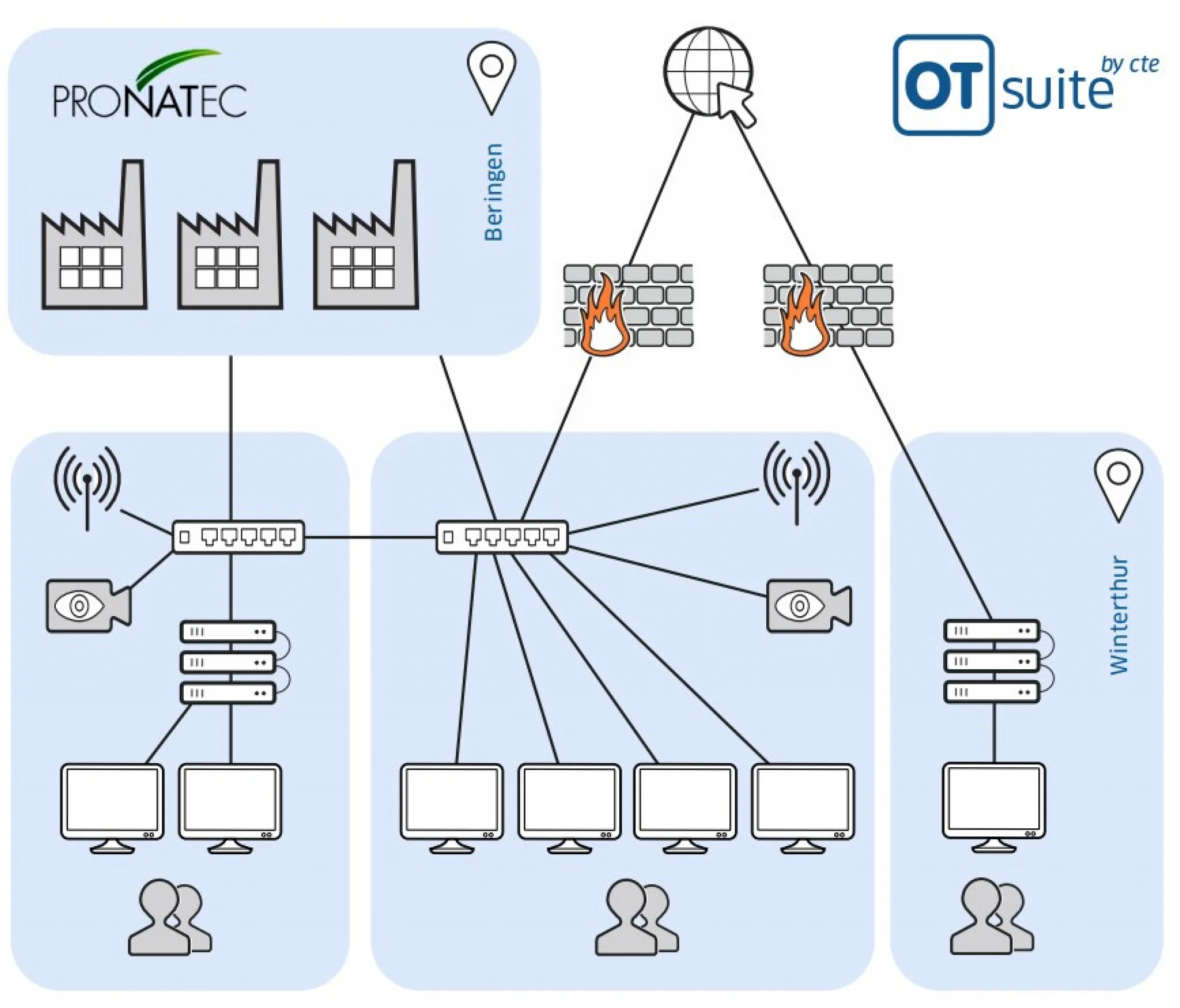

Thanks to our experience from other projects, we were able to determine the requirements for the necessary system landscape at an early stage and identify suitable solutions. After intensive clarifications and good cooperation with the system suppliers, concepts were jointly developed that made it possible to integrate the production systems into the system landscape. Using CTE's proven and standardised concepts and products, we were able to meet the required needs quickly and efficiently. The products from our "OT Infra" portfolio (virtualisation, backup & disaster recovery, system monitoring, remote access) met all the typical requirements of a modern industrial plant. We were also able to successfully implement the Industrial Network and Wireless Network solutions.

A high-availability network was used to securely interconnect the entire production plant. This was specially designed by CTE for industrial environments and met the necessary requirements. The wired network was extended by a centrally manageable wireless network. This enables the use of mobile barcode scanners and handhelds throughout the site. Cyber security was also covered by our concepts and both technical and organisational measures were taken to meet these requirements. Our standardised video surveillance technologies were installed to increase occupational safety.

Thanks to our comprehensive portfolio of industrial IT concepts, all of these solutions were successfully installed, configured and tested at CTE quickly, efficiently and well ahead of the planned commissioning. This meant that all systems could be put into operation on time and without any problems, and the once empty hall was filled with people and machines on schedule. The integration and networking of the various production systems also went smoothly.

Support From Analysis to Maintenance

A framework and maintenance contract was drawn up in order to provide the customer with the best possible support even after the systems were commissioned. This contract enables us to support the entire life cycle of the systems used. We take care of updates and the necessary maintenance of all systems provided by us. In addition to maintenance, we also offer an on-call service that is available at all times in the event of a system failure. In this way, we provide Pronatec with reliable support - from the initial consultation through to the design, implementation, maintenance and standby service for all project phases.