Smart Object Library for Process Automation

The Smart Object Library for Process Automation improves visualisation with zenon and, as well as increasing your efficiency, ensures fewer sources of error. Find out more about the new library for zenon in this technical article.

Everyone knows and understands the importance of a user-oriented, yet consistent visualisation for the operation of an automated system.

During development, the known issues are formulated, discussed and decided upon:

"What is our style guide?"

"What are the design specifications for the project?" or

"Which aspects of automation should be visible to which operator?"

The effort required for both the definition and the consistent implementation of visualisation specifications is significant.

The simplest and most widespread solution to save development time is to use libraries. Software libraries have the following advantages:

The use of predefined building blocks offers the opportunity to develop quickly and deal with the core problems of a project

The time required for repetitive work is massively reduced

Existing modules, which have already been validated, significantly reduce the testing and qualification effort and thus save development time again

A consistent UI/UX design contributes significantly to avoiding possible operating errors, as there are not several different keywords, icons or colours for the same intended use

However, in order to exploit the above-mentioned advantages across multiple projects, a good library must meet the following requirements:

It must be easy to add to existing projects,

it must be easily expandable for additional elements and

it must be easily maintained

Taking these requirements into account, we have developed a new library called Smart Object Library for Process Automation (SOL-PA) based on Smart Objects from the zenon software platform. The library provides the basis for a control-independent visualisation that can be easily adapted and customised.

The library builds on: zenon software platform

zenon is a software platform used for the visualisation and control of automation systems , among other things. This includes batch process execution, data management and reporting. With over 300 native drivers, a wide variety of controllers can be used or exchanged in the same project. For object-oriented programming, zenon offers so-called Smart Objects.

zenon Smart Object (SO) and Smart Object Template (SOT) were introduced with zenon version 8.00 and offer the option of modularly editing individual partial aspects of a zenon project, which can be imported and exported with versioning. Below you will find a brief description of these Smart Objects.

Smart Object Template SOT

As the name suggests, an SOT is the template for one or more SOs. This means that only SOTs can be edited. An SOT offers a subset of options such as images, symbols, interlocks, variables and even drivers.

An SO can only link variables defined in SOTs. Released properties can be used to make properties of elements of the SOT accessible to SOs, e.g. the assignment of system modelling or authorisation.

Smart Object SO

An SO is exactly one instance of an SOT. An SO is zenon project-bound. Instantiation involves two steps:

Assignment of SO variables to project variables

Configuration of the Released Properties

By assigning project variables to SO variables, SO variables can be replaced by project variables and the properties of the SO or project variable can optionally be applied. This offers the advantage that properties for variables have already been set in the SOT, such as limit values, representation or equipment model. Only the data source and addressing are exchanged.

Thanks to their versatility and the possibility of nesting them, SO are ideal for libraries. Combined with the control independence of zenon, the SOL-PA presents itself as a profitable overall package.

What is the Smart Object Library for Process Automation?

In our Smart Object Library for Process Automation (SOL-PA), we have designed a lean, customisable visualisation library with the help of zenons Smart Objects. SOL-PA contains popups and symbols according to IEC 61512 with a focus on process automation in the pharmaceutical environment. This means that SOL-PA has been developed and tested in accordance with GAMP, ISA88.01 and ISA101.01 .

What does SOL-PA contain?

SOL-PA elements are divided into the following four categories:

General: General units that include basic modules of the library (alarm, interlocks or size of popups)

Control modules: Valves and motors

Control: Elements that are used to control CMs or sensors

Sensor: Sensor modules

General and Control contain elements that are used by CMs and sensors, e.g. generic alarm module, interlocks, operating mode. As an SOT can reference and use any number of SOs, each module in these two categories describes a clear usage in sensors or CM SOTs. This ensures that new modules can be added easily and that a module performs exactly one task.

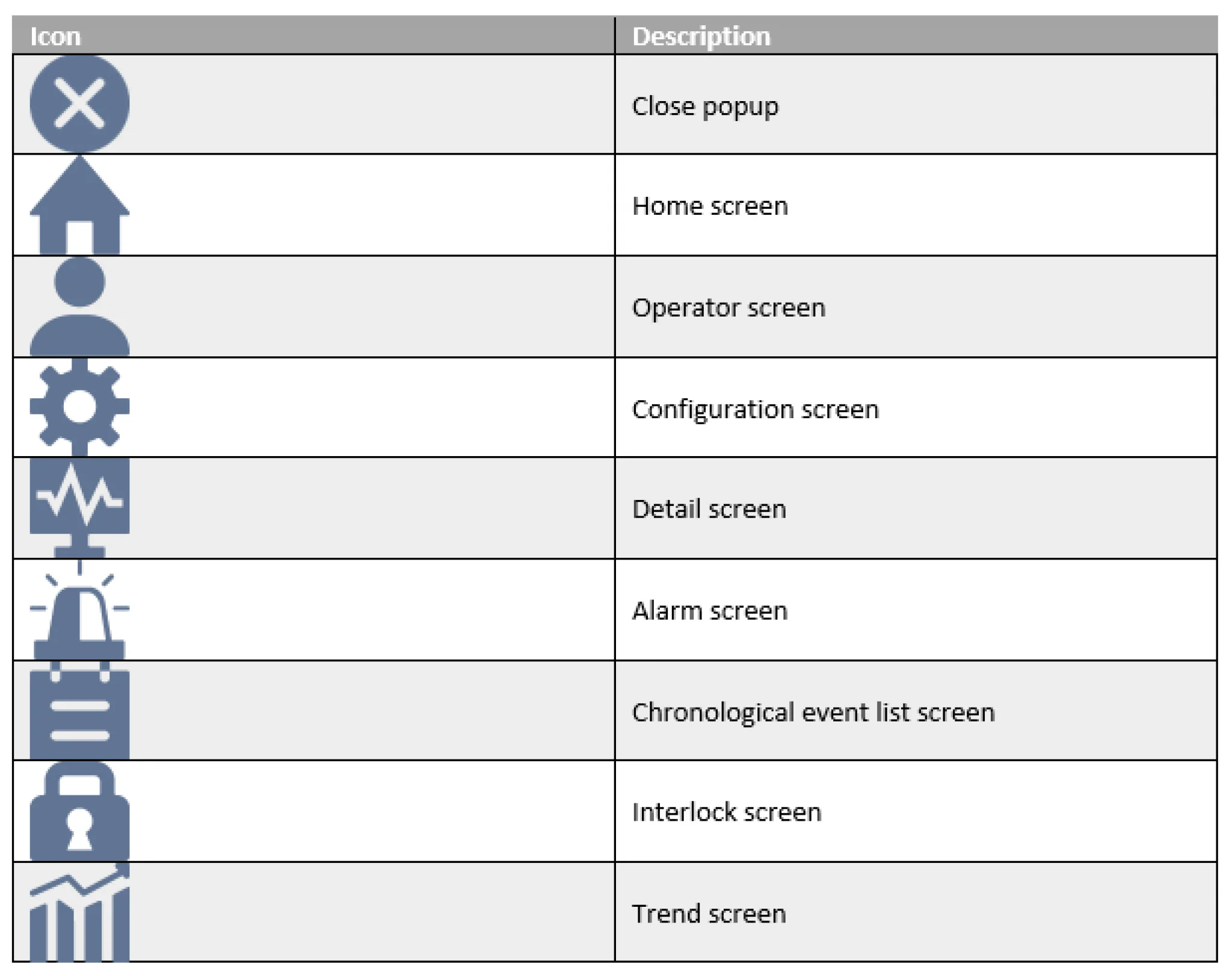

SOL-PA almost only uses icons to describe functions or certain statuses so that the icons can be recognised and don't contain any potential language barriers.

How do you use SOL-PA?

In order to configure a SO with all its functions according to its own requirements, an intuitive interface is necessary

In SOL-PA, all SOTs use the same layout for the released properties. For example, each element offers the option of setting the system model for all variables within the SO or assigning the resource name. This makes it easy to determine which properties a specific SO offers.

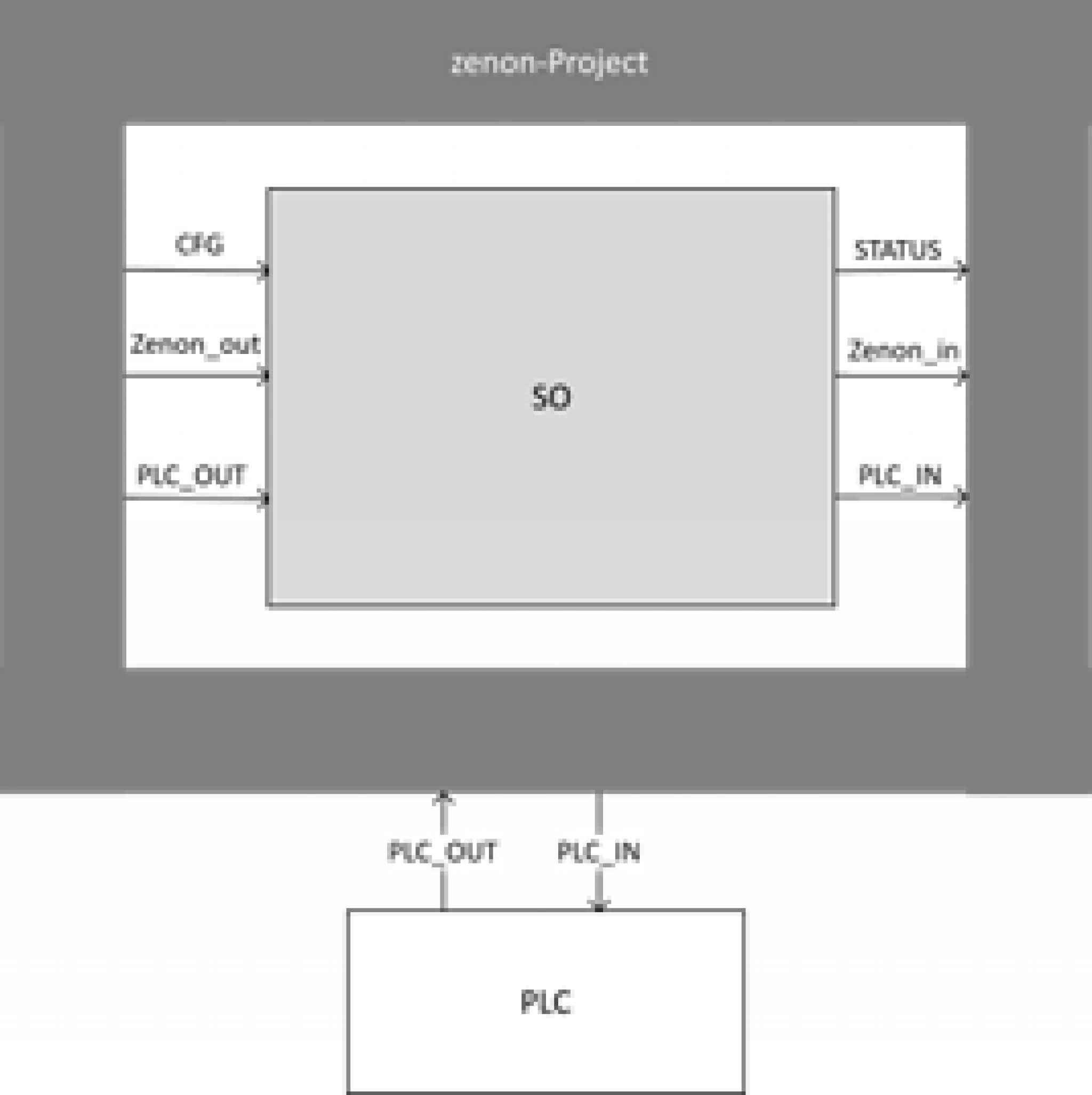

To ensure that only the elements actually required within SOL-PA are defined, SOs can be viewed as a black box.

The figure below visualises the integration of a SOL-PA SO in a zenon project. CFG describes the configuration through the Released Properties, zenon out/in and PLC_OUT/IN represent the zenon project variables used and assigned to SO variables. The differentiation between zenon and PLC variables is intended to clarify where these data points were defined.

This structure ensures that the PLC can be exchanged independently of the visualization project as long as the same data points, which are defined by PLC_OUT/IN, are used. In addition, the encapsulation of the SOs within a project offers the possibility of adapting the display of the SO by the zenon project.

How do I customise the look and feel?

zenon offers the option of saving representations of texts, symbols or entire screen elements as templates (styles) and applying these to existing elements. The colours, fonts and styles used in SOL-PA are specified within the zenon project. This means that if changes to the display, such as the font size, are required for a specific application, this can be adjusted centrally in one place without changing the SOTs.

Who is authorised to operate my system?

Authorisation is an integral part of any operating concept. SOL-PA therefore, offers three different authorisation units: Operator, Supervisor and Maintenance. Each of these three authorisation units can be configured independently of each other and per SO. Everything is possible, from single-level authorisation to Perform, Verify, Approve.

What do the elements look like?

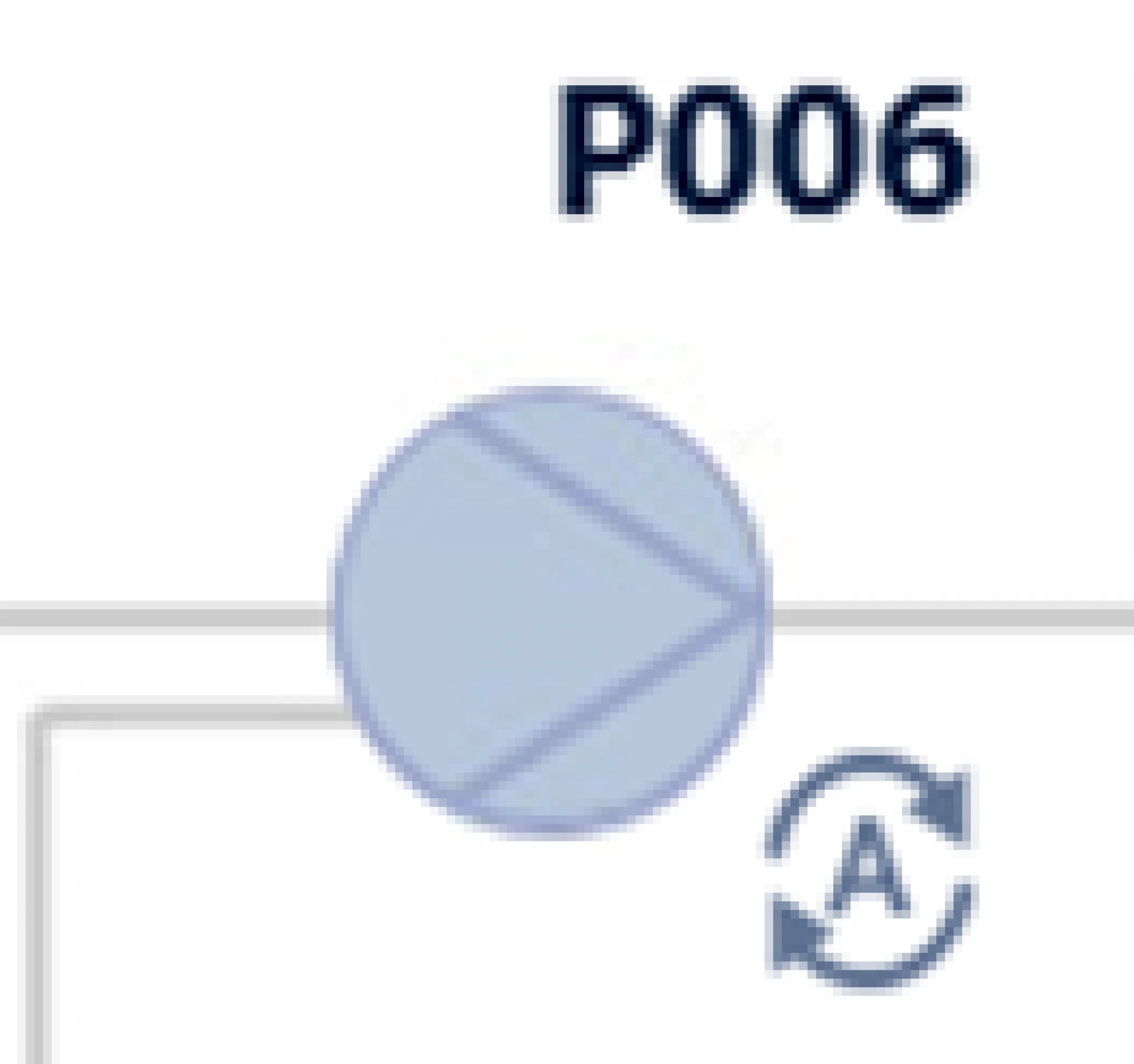

Icons are defined for each CM SOT, which represent the corresponding module in accordance with IEC 61512. In addition to the pure symbol, the designation and the most important statuses are also displayed as icons. This includes alarm, simulation, interlock and operating mode. This illustration shows a pump symbol with operating mode and labeling.

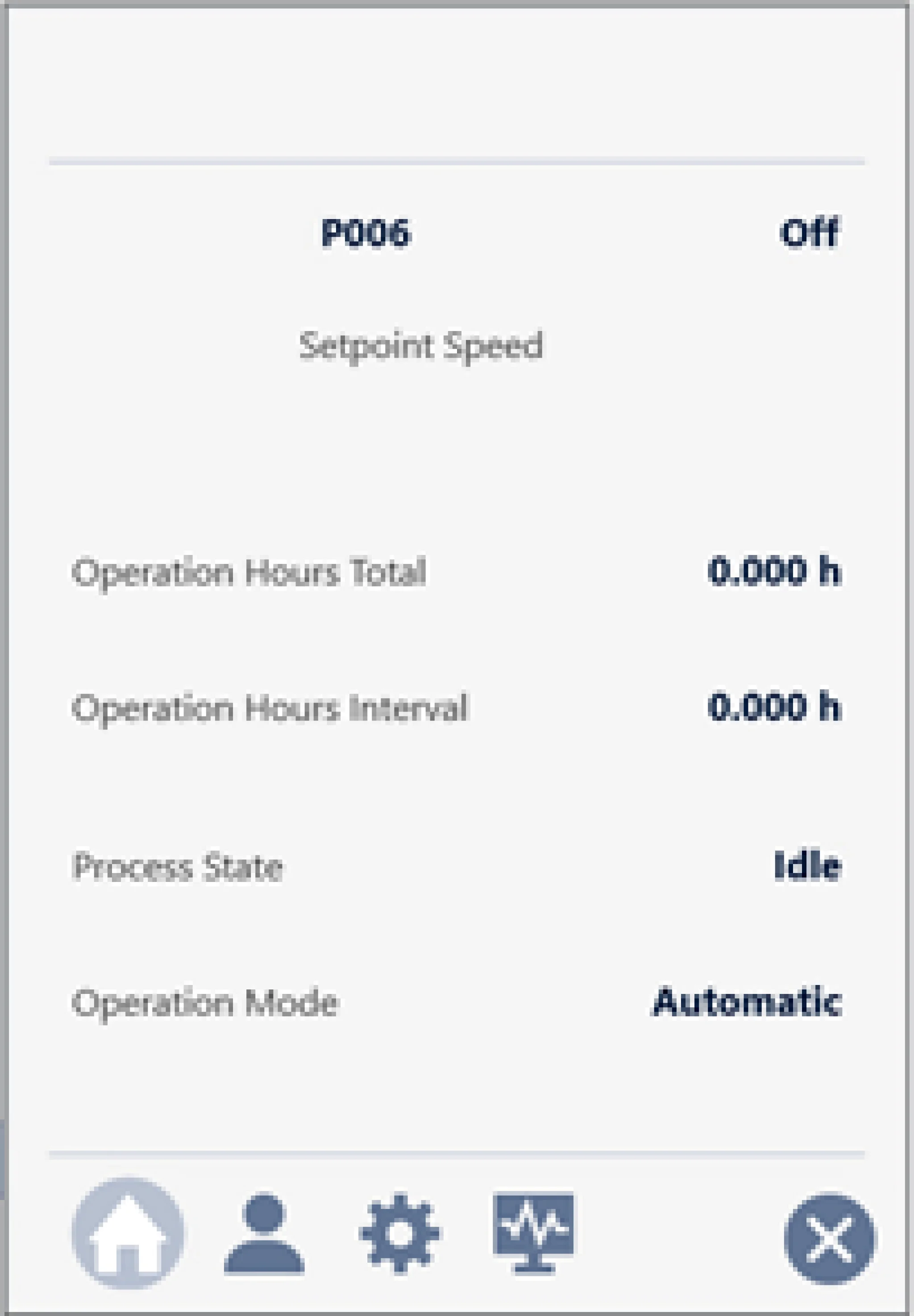

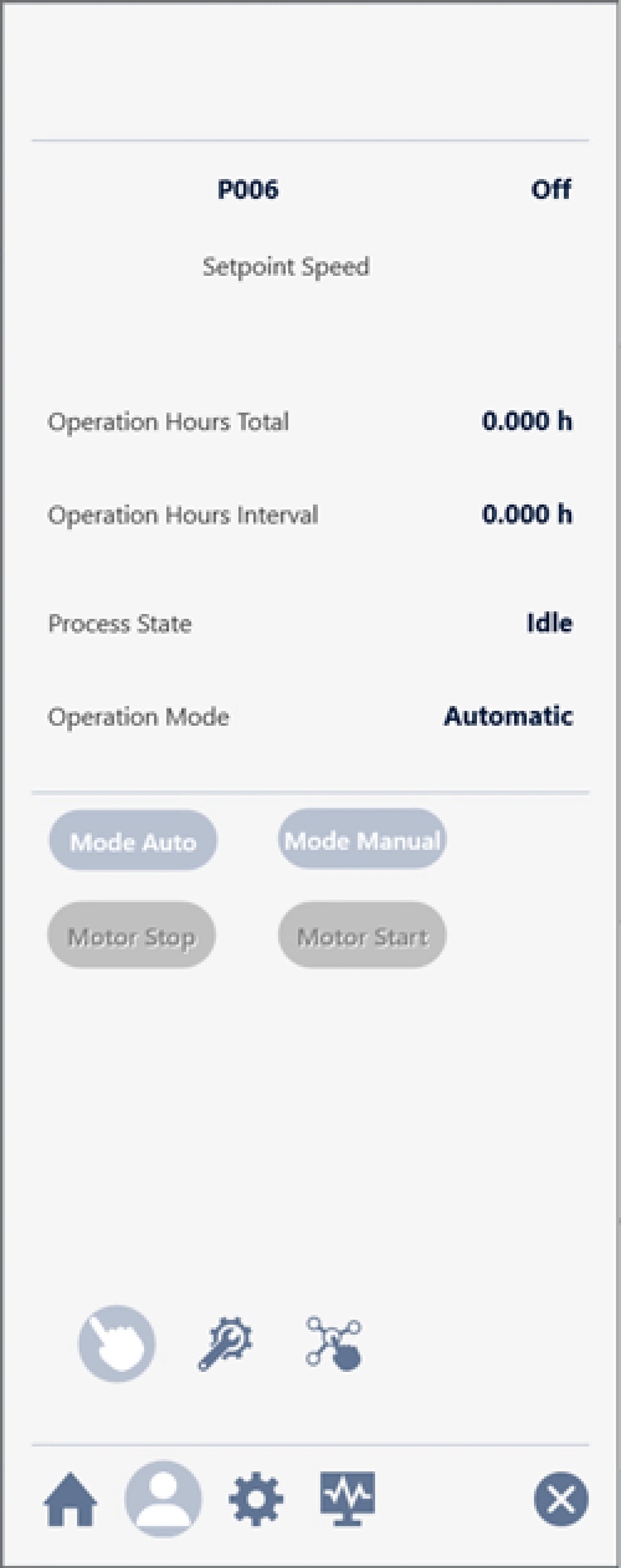

When clicking on the icon, a pop-up opens, providing additional information. Each pop-up contains the following four pages:

Start screen: Display of the current status of the module

Operation: Provides options for controlling the module and changing the operating mode

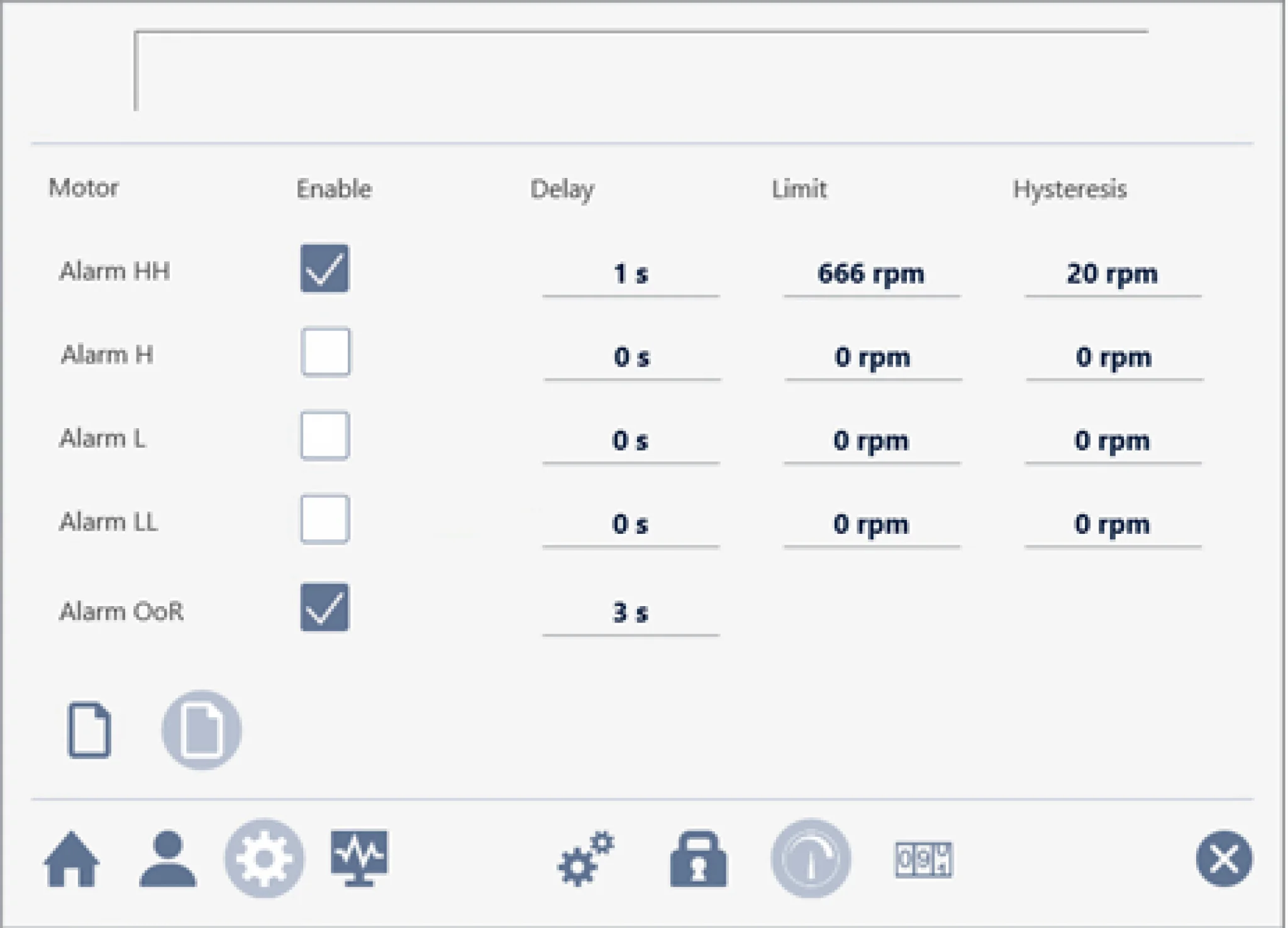

Configuration: Provides properties of each module for configuration or reference. This includes alarm limits, delays, hysteresis, activation/deactivation, sensor input ranges etc.

Detail: Provides extended information such as trend or interlock overview

There is also a status bar with the most important information (interlock and alarm status).

These three illustrations show the home screen, the operator screen for manual operation and, at the bottom, the alarm configuration of a pump with variable frequency drive.

The alarm configuration consists of a status bar at the top, a menu bar at the bottom of the screen and the main content. In this case, the configuration of five alarms. Whereby limit alarms can be configured with delay, limit value, hysteresis and activation/deactivation.

Conclusion

SOL-PA offers the possibility to use PLC independent visualisation blocks in zenon, which are already validated. In addition, SOL-PA can be easily extended and the display customised. This enables shorter project times and thus, to be able to focus on the core aspects of the project instead of having to deal with repetitive aspects.